TM 5-3895-383-24

Metering Pump (Steering)

SMCS Code: 4312

Part No.: 1G-9787

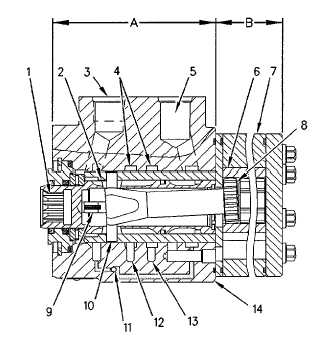

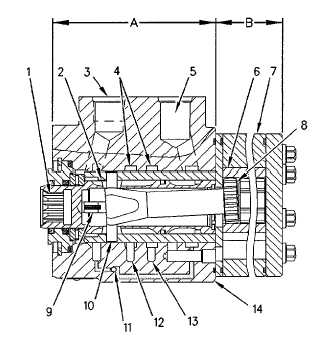

Illustration 19

Metering Pump

(1) Inner Spool. (2) Sleeve. (3) Outlet port. (4) Load sensing

line port. (5) Inlet port. (6) Rotor. (7) Rotor ring. (8) Drive

shaft. (9) Centering springs. (10) Pin. (11) Internal check

valve. (12) Left turn port. (12) Right tun port. (13) Housing.

The metering pump is made up of the following two sections:

Control section (A)

Metering section (B)

The two sections are connected by hydraulics and by

mechanics. The two sections work together in order to send oil

to the steering cylinders.

Pump oil goes through inlet port (5) into control section (A).

When the steering wheel is turned, control section (A) sends oil

to metering section (B). Metering section (B) produces a

specific amount of oil flow. Metered oil from metering section

(B) is then directed by control section (A) to either left turn port

11 or right turn port (13).

Metering section (B) is a small hydraulic pump. The hydraulic

pump produces a metered amount of oil flow. Then, the

metered oil is directed by the control section (A) to the steering

cylinders.

The direction and the speed are controlled by the metering

pump. As the steering wheel is turned faster, there is an

increase in the flow of oil from the metering pump to the

cylinders. The increased flow causes the cylinders to move

faster. The result is faster movement of the machine.

Oil Flow

Oil flows through outlet port (3). When the steering wheel is in

the NO STEER position, the oil is stopped by spool (1). The oil

cannot flow to the metering pump to the steering cylinders until

the steering wheel is turned.

The steering column is connected to the spool (1) by a shaft

and a spline coupling.

When the steering wheel is turned, spool (1) turns a small

amount until springs (9) are compressed. When the drive

pinion contacts the ends of the slots, the sleeve (2) also turns.

While the steering wheel is turning, the spool and the sleeve

are spread apart by a few degrees. The spool and the sleeve

rotate as one unit. The centering springs are compressed.

The initial movement of the spool opens the oil passages

between the control section and the metering section. This

allows the oil flow from inlet pod (5) to go to the metering

section.

12-20