TM 5-3895-383-24

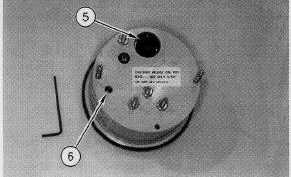

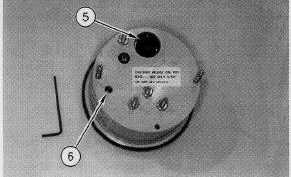

Illustration 75

(5) Dial. (6) Small calibration screw.

7.

Set large dial (5) on 8.

8.

Use small calibration screw (6) in order to calibrate the

gauge. Use a 2.0 mm (5/64 inch) allen wrench in order

to adjust the small calibration screw.

NOTE:

If the reading from VPM gauge (3) is significantly

different from the reading for 133-0963 Drum

Vibration

Tachometer

(4)

or

the

133-9905

Frequency Meter, the magnetic sensor output

should be verified before tachometer (3) is

calibrated.

Vibratory Magnetic Sensor - Test and Adjust

SMCS Code: 6606-025-NS; 6606-081-NS

Personal injury or death can result from sudden machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

NOTICE

To avoid damage to the vibratory system during testing,

always perform the testing with the vibratory drum on top

of tires or on loose dirt. Tires will simulate a non-

compacted soil condition.

Never operate the vibratory system when the machine is

on concrete.

NOTICE

If a testing time longer than three (3) minutes is required,

rotate the drum periodically in order to lubricate the

eccentric weight shaft bearings.

Table 17

Tools Needed

6V-7070

Digital Multimeter (or equivalent)

1

NOTE:

The hydraulic oil temperature should be at least

38° C (100° F).

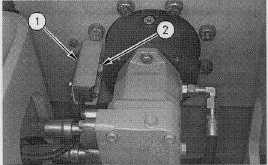

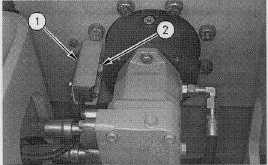

Illustration 76

Right Side Of Drum As Viewed From Operator Seat

(1) Guard. (2) Magnetic sensor.

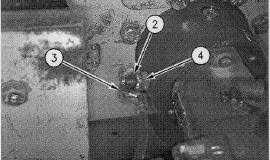

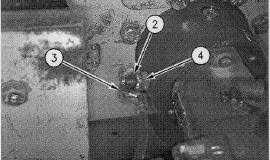

Illustration 77

Vibratory Magnetic Sensor Location

(2) Magnetic sensor. (3) Wires. (4) Case.

1.

Remove guard (1) from top of magnetic sensor (2).

2.

Remove rubber boot. Disconnect two wires (3) from

magnetic sensor (2).

11-64