TM 5-3895-383-24

2.

Make sure that the manual directional control valve (4)

is in the neutral position.

3.

Disconnect electrical connector (2) for the neutral start

switch (1).

4.

Clip the multimeter leads to the two pins in the electrical

connector (2). Switch the multimeter to the position that

will measure continuity.

5.

Loosen locknut (5) that is holding the neutral start

switch.

6.

Turn the neutral start switch until the beep from the

multimeter cannot be heard. Turn the switch in the

counterclockwise direction until the beep is heard.

7.

Hold the neutral start switch and tighten the locknut.

Charge Relief Valve - Test and

Adjust

SMCS Code: 5117-025-PX; 5117-081-PX

Table 13

Required Tools

Part Number

Description

Quantity

8T-0855

Pressure Gauge

4000 kPa

(580 psi)

1

Personal injury or death can result from sudden machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

Personal injury can result from hydraulic oil pressure and

hot oil.

Hydraulic oil pressure can remain in the hydraulic system

after the engine has been stopped. Serious injury can be

caused if this pressure is not released before any service

is done on the hydraulic system.

Make sure all of the attachments have been lowered, oil is

cool before removing any components or lines. Remove

the oil filler cap only when the engine is stopped, and the

filler cap is cool enough to touch with your bare hand.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide" for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

NOTE:

A charge relief valve is located in both the propel

pumps. The charge relief valve in the drum propel

pump should be the controlling relief valve (lower

pressure setting). If the setting for the drum

charge relief valve does not change, the axle

charge relief valve may be set too low.

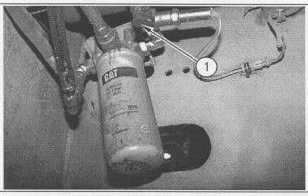

Illustration 71

Charge Pressure Test

(1) Charge pressure test port.

10-68