TM 5-3895-383-24

Check the following parameters if the travel speed is not

correct.

1.

Pump efficiency.

2.

Charge relief valve setting.

3.

Check the main relief valve setting.

4.

Make sure that the machine is in the HIGH SPEED

range.

5.

Make sure that the linkage rod between the propel

pumps is adjusted correctly.

6.

Check the axle propel motor for the correct minimum

displacement adjustment.

Piston Pump Relief Valve

(Axle Propel and Drum Propel) -

Test and Adjust

SMCS Code: 3203-025-PV; 3203-081-PV

Table 8

Required Tools

Part number

Description

Quantity

8T-0861

Pressure Gauge

1

60000 kPa

(8700 psi)

Personal injury or death can result from sudden, machine

movement.

Sudden movement of the machine can cause injury to

persons on or near the machine.

To prevent injury or death, make sure that the area around

the machine is clear of personnel and obstructions before

operating the machine.

Escaping fluid under pressure, even a pinhole size leak,

can penetrate body tissue, causing serious injury, and

possible death. If fluid is injected into your skin, it must

be treated immediately by a doctor familiar with this type

of injury.

Always use a board or cardboard when checking for a

leak.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, “Caterpillar Tools

and Shop Products Guide” for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

NOTE:

Follow the same test procedure and the same

adjustment procedure for the relief valves on the

axle propel pump and the drum propel pump.

Before you conduct the test procedure on the main relief

valves, the following steps must be followed:

Place the propel control lever in NEUTRAL position.

Place the machine in position against a solid, stationary

object such as a loading dock. The wheels may be

blocked and the drum may be blocked instead of placing

the machine against a stationary object.

Make sure that the parking brake is applied.

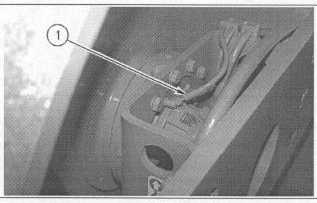

Illustration 63

Drum Dive Motor

(1) Brake line.

1.

Remove brake line (1) from the drum drive motor. Plug

the brake line and cap the fittings.

10-63