TM 5-3895-383-24

The drum propel pump is mounted in tandem with the axle

propel pump. The charge pressure for the propel system is

supplied by the steering pump. When the engine is operating,

drive shaft (1) and barrel assembly (10) are rotating. There are

nine pistons (13) in the barrel assembly. Port plate (5) and

swashplate (14) are fastened to case (9). The port plate and

the swashplate do not rotate. Spring washers (12) keep a

force on the barrel assembly in order to make a high pressure

seal between the barrel assembly and the pod plate. When

the barrel assembly is rotating, each piston (13) follows the

angle of the swashplate. If the swashplate angle is at zero, the

pistons do not move in and out of the barrel assembly and

there is no oil flow.

The position of the swashplate is controlled by the manual

directional control valve (4) and servo valve (3). Movement of

the propel control lever moves the directional control valve.

The directional control valve routes charge oil into the servo

valve. The servo valve controls the direction and the amount

of the swashplate angle.

The steering pump maintains charge oil in the propel pump in

order to keep the barrel assembly full of oil. The charge oil

lubricates the pump components. The internal loss of oil due

to leakage is replenished by the charge oil. The charge oil is

also used in order to release the brakes and the charge oil will

provide the shift valve with oil.

Oil flows from the drum propel pump to the drum propel motor

and back to the drum propel pump by way of inlet/outlet ports

(6) and (8). The position of the swashplate determines the

direction of flow as well as the high pressure side of the two

loop lines.

Servo Valve (Piston Pump)

SMCS Code: 3205

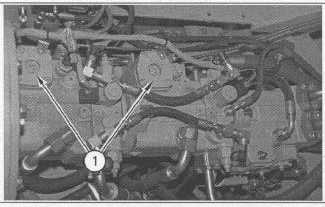

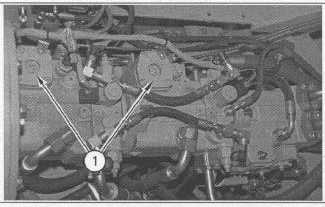

Illustration 23

Location of Servo Valves on the Propel Pumps

(1) Servo valves.

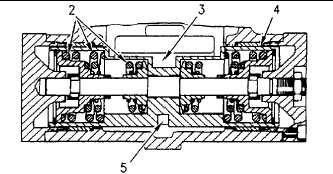

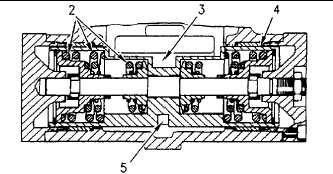

Illustration 24

Servo Valve

(2) Springs. (3) Slot for control valve. (4) Servo piston. (5)

Slot for swashplate control.

Oil from the control valve goes to either the right or the left end

of servo piston (4). Servo piston (4) also receives a

mechanical input from the lever that is connected to slot (3).

The swashplate control is attached to the servo piston in slot

(5). When the servo piston moves, the lever moves the

swashplate to the angle that corresponds to the position of the

servo piston.

When the charge pressure is relieved by the POR valve,

springs (2) move servo piston (4) toward the centered position.

This reduces the angle of the swashplate in the pump which

causes the pump output to be reduced.

10-32