TM 5-3895-383-24

Engine

Remove & Install Engine 1000-010

Tools Needed

A

6V-3145

Load Leveler

2

Start By:

a.

*tilt operator's platform or tilt cab

* This procedure is in the Machine Systems Disassembly &

Assembly module, Form No. KENR7037.

1.

Open the engine enclosure.

2.

Move the disconnect switch to the OFF position.

At operating temperature, the engine coolant is hot and

under pressure. Steam can cause personal injury. Check

the coolant level only after the engine has been stopped

and the fill cap is cool enough to touch with your bare

hand. Remove the fill cap from the radiator slowly to

relieve pressure. Cooling system conditioner contains

alkali. Avoid contact with the skin and eyes to prevent

personal.

3.

Drain the coolant from radiator into a suitable container.

The capacity of the cooling system is 30.0 liters (8 U.S.

gallons).

At operating temperatures, the oil tank is hot and under

pressure. Hot oil can cause burns. Remove the fill plug

only when the engine is stopped and when the fill plug is

cool enough to touch with your bare hands.

NOTE:

Identify all hydraulic lines as they am removed for

reinstallation purposes. Cap and plug all lines

and fittings to prevent any contaminants from

entering the system.

4.

Release the pressure in the hydraulic system by slowly

loosening the fill cap located on the top of the hydraulic

oil tank.

5.

Drain the hydraulic oil from the hydraulic oil tank. The

capacity of the hydraulic oil tank is 80 liters (21.1 U.S.

gallons).

NOTE:

Use steps 6 through 14 only if the machine is

equipped with air conditioning.

6.

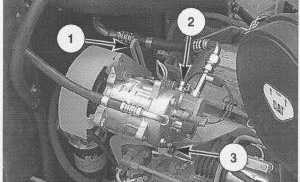

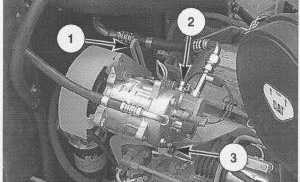

Disconnect two electrical connectors (2).

7.

Remove the bolt from air conditioner compressor strap

(1).

8.

Remove bolt (3) and remove air conditioning unit. Move

the air conditioning unit out of the way.

9.

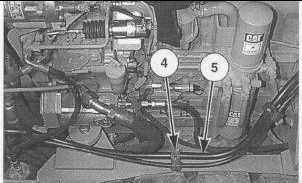

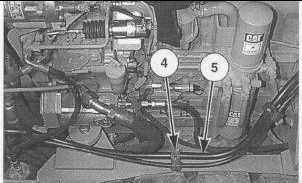

Remove three clamps (4) from two hose assemblies (5).

9-16