TM 5-3895-383-24

The two piece pistons consist of an alloy steel crown

connected to an aluminum skirt by the piston pin. Piston

cooling jets in the cylinder block spray oil to the underside of

the piston crown to cool the piston. All three rings are located

in grooves in the piston crown. Holes in the oil control (lower)

ring groove allow oil to return to the crankcase.

The connecting rod has a taper on the pin bore end. This

gives the rod and piston more strength in the areas with the

most load. Two bolts hold the rod cap to the rod. This design

keeps the rod width to a minimum, so that the rod can be

removed through the cylinder.

Crankshaft

The crankshaft changes the combustion forces in the cylinder

into usable rotating torque which powers the equipment. A

vibration damper is used at the front of the crankshaft to

reduce torsional vibrations (twist on the crankshaft) that can

cause damage to the engine.

The crankshaft drives a group of gears on the front of the

engine. The gear group drives the oil pump, camshaft,

governor, and the gear driven air compressor and/or power

steering pump. In addition to this, the front belt pulleys on the

crankshaft drive the radiator fan, water pump, alternator and

freon compressor.

Hydrodynamic seals are used at both ends of the crankshaft to

control oil leakage. The hydrodynamic grooves in the seal lip

move lubrication oil back into the crankcase as the crankshaft

turns. The front seal is located in the front housing. The rear

seal is installed in the flywheel housing.

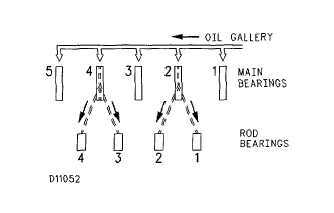

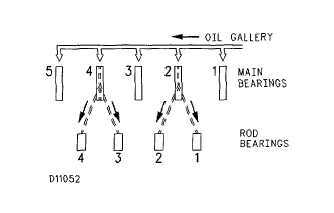

Schematic Of Oil passages In Crankshaft (4 cylinder)

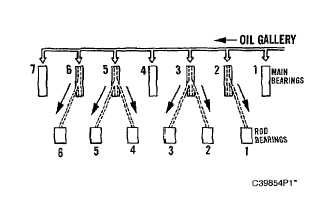

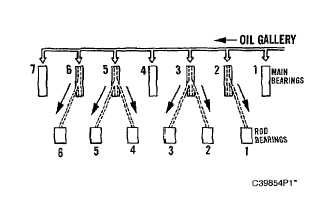

Schematic Of Oil Passages In Crankshaft (6 cylinder)

Pressure oil is supplied to all main bearings through drilled

holes in the webs of the cylinder block. The oil then flows

through drilled holes in the crankshaft to provide oil to the

connecting rod bearings. The crankshaft is held in place by

seven main bearings. A thrust main bearing next to the rear

main bearing controls the end play of the crankshaft.

6-24