TM 5-3895-383-24

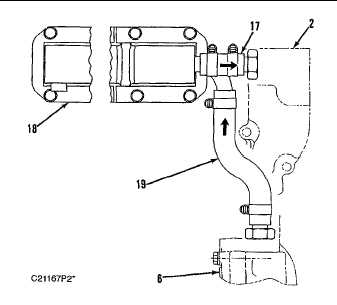

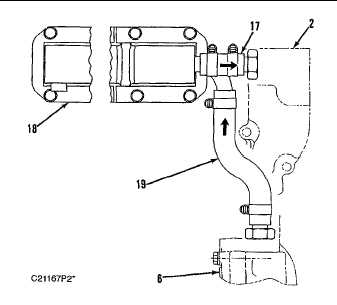

Aftercooler Coolant Connections

(2) Water temperature regulator housing. (6) Water pump.

(17) Outlet hose. (18) Aftercooler. (19) Inlet hose.

The aftercooler equipped on some engines is tied into the

jacket water coolant system. Inlet hose (19) delivers coolant to

aftercooler (18) from a separate outlet of water pump (6). After

the coolant has circulated through the aftercooler core, it goes

through aftercooler outlet hose (17) and enters regulator

housing (2).

Basic Block

Cylinder Block And Head

The cylinder block has five main bearings for the four cylinder

engine and seven main bearings for the six cylinder engine.

Two bolts hold each bearing cap to the block.

Removal of the oil pan allows access to the crankshaft, main

bearings caps, piston cooling jets, and oil pump.

The camshaft compartment is accessible through covers on

the left side of the cylinder block. These side covers also

support the pushrod lifters. The camshaft is supported by

bearings pressed into the cylinder block. There are five

camshaft bearings for the four cylinder engine and seven

camshaft bearings for the six cylinder engine.

The cylinder head is separated from the block by a steel and

non-asbestos fiber gasket. Coolant flows out of the block

through gasket openings and into the head. This gasket also

seals the oil supply and drain passages between the block and

the head. The air inlet ports are on the top of the head, while

the exhaust ports are located on the right side of the head.

There is one intake and one exhaust valve for each cylinder.

Valve guides are pressed into the cylinder head. The fuel

injector is located between the two valves. Fuel is injected

directly into the cylinders at very high pressure. A pushrod and

rocker arm system controls the valves and fuel injectors.

Pistons, Rings And Connecting Rods

One piece aluminum pistons are used in most applications.

Engines with higher cylinder pressures require two piece

pistons. Refer to the parts book to obtain information about the

type of pistons used in a specific engine.

The aluminum one piece pistons have an iron band for the top

two rings. This helps reduce wear on the compression ring

grooves. Oil from the piston cooling jets spray the underside of

the pistons. This cools the pistons and improves piston and

ring life. The pistons have three rings, two compression rings

and one oil ring. All the rings are located above the piston pin

bore. The oil ring is a standard (conventional) type. Oil returns

to the crankcase through holes in the oil ring groove. The top

two rings are the KEYSTONE type, which are tapered. The

action of the ring in the piston groove, which is also tapered,

helps prevent seizure of the rings caused by too much carbon

deposit.

6-23