TM 5-3895-382-24

Swashplate Neutral Adjustment Procedure

(9XL229-Up, 3WZ158-Up, 2JM579-Up, 4JZ122-Up, 3TM706-

Up, 5BZ119-Up, 6EN127-Up, 2TN118-Up, 1ZN121-Up, 1FS1-

Up, 1XZ1-Up)

Tools Needed

6V-7830

Tetra Gauges

1

Make

reference

to

WARNING

on

first

page

of

Troubleshooting.

NOTE:

Tests should be performed on tires or loose dirt.

Tires are recommended. Never operate the

vibratory system when the machine is on

concrete.

NOTE:

Make sure the parking brake is applied, and the

propel control lever is in neutral.

Flushing Manifold.

(1) Test port for vibratory high amplitude) pressure. (2) Test port for

vibratory (low amplitude) pressure. (3) Servo port.

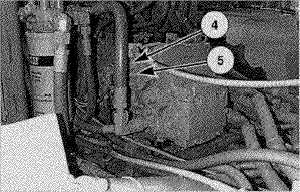

Vibratory Pump.

(4) Servo port. (5) Pump neutral adjustment.

1.

Connect two 60 000 kPa (8700 psi) pressure gauges to

test ports (1) and (2).

2.

Remove plugs from servo ports (3) and (4). Install a

3445 kPa (500 psi) minimum pressure hose between

servo port (3) and servo port (4). This will cross port the

servo and remove the effects of any control pressure on

the servo piston.

3.

Start and slowly accelerate the engine to full throttle.

Operate the vibratory system in both high and low

amplitudes several times and then stop the vibratory

system.

4.

With the servo cross-port line installed, note the system

pressure gauge readings with engine running at low

idle. The difference in the system pressure gauge

readings is the offset pressure.

NOTE:

To achieve finer gauge resolution, lower pressure

gauges will be required. 60 000 kPa (8700 psi)

pressure gauges are used at the beginning to

prevent gauge damage.

5.

If the offset pressure is not zero, loosen the pump

neutral adjustment locknut with a 17 mm hex wrench.

Turn the pump neutral adjustment screw (5) with a 7

mm hex wrench until the system pressure gauge

readings are equal.

6.

Turn the pump neutral adjustment screw (5) clockwise

until one of the gauges registers an increase in system

pressure. Note the position of the pump neutral

adjustment screw (5).

7.

Turn

the

pump

neutral

adjustment

screw

(5)

counterclockwise until the other gauge registers an

increase in system pressure. Note the position of the

pump neutral adjustment screw (5).

8.

Turn the pump neutral adjustment screw (5) to a

position halfway between the positions noted above.

The system pressure gauges should indicate equal

pressures.

9.

Once the swashplate neutral has been found, hold the

servo adjustment screw from turning and torque the

pump neutral adjustment locknut to 28 to 51 Nm (21 to

37 lb-ft).

10.

Stop the engine. Remove the pressure gauges and

servo cross port line. Reinstall the plugs in the servo

pods (3) and (4).

13-34