TM 5-3895-382-24

VPM Measurement Tests

If the hand held meter is correct and the vpm meter does not

accurately indicate system frequency, check the following

procedures to determine the cause, and repair.

Magnetic Sensor Voltage Test

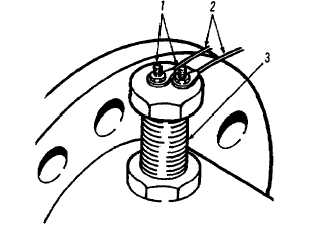

Magnetic Sensor.

(1) Terminals. (2) Wires. (3) Case.

1.

Disconnect two electrical wires (2) from magnetic

sensor.

2.

Set a voltmeter on lowest AC setting. Attach voltmeter

leads to magnetic sensor terminals (1).

3.

Start engine and run at full throttle.

4.

Move vibratory control switch to the low-amplitude

position.

5.

There should be a reading on the voltmeter as the

magnetic sensor picks up pulses from the sprocket as

the drive shaft rotates.

6.

If no reading is obtained, the magnetic sensor may be

out of adjustment, or may need to be replaced.

7.

Shut engine OFF.

Magnetic Sensor Resistance

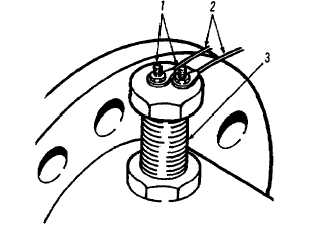

Magnetic Sensor.

(1) Terminals. (2) Wires. (3) Case.

1.

Disconnect two electrical wires (2) from magnetic

sensor.

2.

Touch the leads of an ohmmeter to terminals (1).

Resistance should be 265 30 ohms. If not, replace

the magnetic sensor.

3.

Set the ohmmeter on its highest setting.

4.

Attach one ohmmeter lead to one of the magnetic

sensor terminals (1). Touch the other ohmmeter lead to

the magnetic sensor case (3).

5.

Electrical resistance should be infinite. If the ohmmeter

gives any reading, the magnetic sensor should be

replaced.

6.

Repeat Steps 4 and 5 for the other terminal (1) of the

magnetic sensor.

13-38