TM 5-3895-382-24

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide" for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

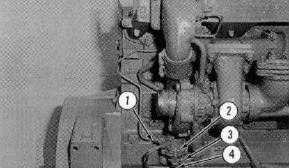

Illustration 16

Typical example.

1.

Inspect the condition of the gasket. Replace the gasket,

if necessary.

2.

Ensure that the rocker arm for the fuel transfer pump is

not under pressure.

3.

Install the gasket and fuel transfer pump (2). If fuel

transfer pump (2) is difficult to install, rotate the

crankshaft.

4.

Install two lock plates (4).

5.

Install four bolts (3). Tighten the bolts to a torque of

22 Nm (16 lb-ft).

6.

Connect two fuel lines (1).

7.

Loosen the vent screw on the top of the fuel filter and

operate the priming lever on the fuel transfer pump in

order to remove the air from the fuel system. When only

fuel comes out of the vent screw, tighten the vent screw.

8.

Start the engine and check the fuel system for fuel leaks

And for air leaks.

Fuel Injection Lines - Remove and Install

SMCS Code: 1252-010

Removal Procedure

Start By:

a.

Remove the fuel filter base. Refer to Disassembly

and Assembly, "Fuel Filer Base - Remove and Install".

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, testing,

adjusting and repair of the product. Be prepared to collect

the fluid with suitable containers before opening any

compartment or disassembling any component containing

fluids.

Refer to Special Publication, NENG2500, "Caterpillar Tools

and Shop Products Guide" for tools and supplies suitable

to collect and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

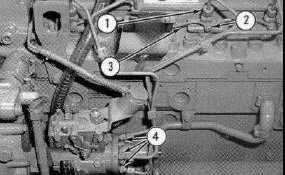

Illustration 17

1.

Disconnect four fuel injection lines (1) from the fuel

injection nozzles.

2.

Cap all openings or plug all openings immediately.

7-10