TM 5-3895-382-24

Clearance between the ends of an oil control ring in a cylinder

liner without any wear .......................................... 0.38 to 0.84 mm

(.015 to .033 inch)

(4)

Diameter of new piston pin .............38.095 to 38.100 mm

(1.4998 to 1.5000 inch)

Bore in piston for pin ....................................38.103 to 38.109 mm

(1.5000 to 1.5004 inch)

Piston height above cylinder block

(not shown) ........................................................... 0.14 to 0.36 mm

(.005 to .014 inch)

Type 2 Engines and 7BJ Engines

NOTE:

For a complete description of Type 1 and Type 2

engines, refer to the Specifications Module,

"Engine Design" for more information.

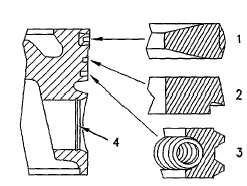

Illustration 47

NOTE:

The word "Front" or an arrow which is marked on

the piston crown must be toward the front of the

engine. If the piston crown is not marked, put the

narrowest side of the piston crater toward the

side of the engine with the fuel injection pump.

The shortest distance between the edge of the

piston crater and the edge of the piston is the

narrowest side of the piston crater.

NOTE:

Be sure that the ring end gaps of all the piston

rings have 120 degrees spacing from each other.

NOTE:

Refer

to

Systems

Operation,

"General

Information" for the location of the serial number.

Turbocharged Engines

(1)

Top piston ring

Shape of groove in piston for top ring ..................................Taper

Shape of top ring .....................................................................Taper

Clearance between the ends of the top ring in a cylinder liner

without any wear .................................................. 0.28 to 0.63 mm

(.011 to .025 inch)

NOTE:

Install the word "TOP" toward the top of the

piston. New top rings have a red identification

mark which must be on the left of the ring gap

when the intermediate ring is installed on an

upright piston.

(2)

Intermediate ring

Width of groove in piston for

intermediate ring ................................................... 2.56 to 2.58 mm

(0.101 to 0.102 inch)

Thickness of intermediate ring ........................... 2.48 to 2.49 mm

(0.097 to 0.098 inch)

Clearance between groove and

intermediate ring.................................................... 0.07 to 0.11 mm

(.003 to .004 inch)

Clearance between the ends of an intermediate

ring in a cylinder liner without any

wear ........................................................................ 0.40 to 0.65 mm

(.016 to .026 inch)

NOTE:

Install the word "TOP" toward the top of the

piston. New intermediate rings have a green

identification mark which must be on the left of

the ring gap when the intermediate ring is

installed on an upright piston.

(3)

Oil control ring

Width of groove in piston for oil

control ring ............................................................. 3.54 to 3.56 mm

(.139 to .140 inch)

Thickness of oil control ring ................................ 3.47 to 3.49 mm

(.136 to .137 inch)

Clearance between groove and oil

control ring ............................................................. 0.05 to 0.09 mm

(.002 to .004 inch)

Clearance between the ends of an oil control ring in a cylinder

liner without any wear .......................................... 0.38 to 0.83 mm

(.015 to .033 inch)

NOTE:

A pin is used in order to hold both ends of the

spring of the oil control ring in position. The ends of

the spring of the oil control ring must be 180

degrees opposite the end gap of the oil control ring.

(4)

Diameter of new piston pin..............39.694 to 39.700 mm

(1.5628 to 1.5630 inch)

Bore in piston for pin ....................................39.703 to 39.709 mm

(1.5631 to 1.5633 inch)

Piston height above cylinder block

(not shown) ........................................................... 0.36 to 0.50 mm

(.014 to .020 inch)

5-35