TM 5-3895-382-24

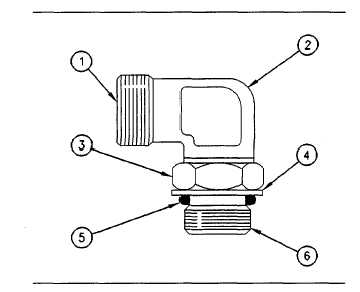

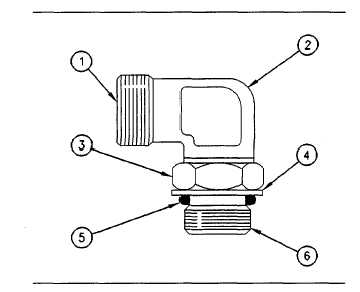

Illustration 3

Elbow body assembly

(1) End of the fitting body that connects to the tube. (2) Fitting body.

(3) Locknut. (4) Backup washer. (5) O-ring seal. (6) End the fitting

that goes into the other part.

1.

Put locknut (3), backup washer (4) and O-ring seal (5)

as far back on fitting body (2) as possible. Hold these

components in this position. Turn the fitting into the part

that is used for the fitting. Turn the fitting until backup

washer (4) contacts the surface of the part that is used

for backup washer (4).

2.

To put the fitting assembly in the correct position, turn

fitting body (2) outward to a maximum of 360 degrees.

Tighten locknut (3) to the torque that is shown in the

correct chart for the fitting that is used.

NOTE: If the fitting is a connector

(straight fitting), the hex on the

body takes the place of the

locknut. To install this type of

fitting, tighten the hex against the

face of the part for the hex.

Torques for Flared and O-Ring Fittings

SMCS Code: 7553

The torques that are shown in Table 7 and in Table 8 should

be used on the nut of the following fittings: 37 degree flared

fittings, 45 degree flared fittings, inverted flared fittings, O-ring

plugs for a recessed drive, O-ring fittings for the air

conditioning, and swivel nuts. The torques should be used for

applications that allow the following working pressures: 7750 to

34,450 kPa (1125 to 5000 psi). The torque depends on the

size of the fitting and the type of the fitting.

37 Degree Flared Fittings

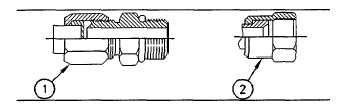

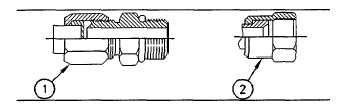

Illustration 4

(1) 37 degree flared fitting. (2) Swivel nuts.

4-7