TM 5-3895-379-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

Table 2. Electrical Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. Check for power to main relay 1. If 24 to 28 Vdc are not measured

15. No Power to Accessories With The

Engine Running.

from alternator circuit breaker.

at input terminal (wire 109-OR),

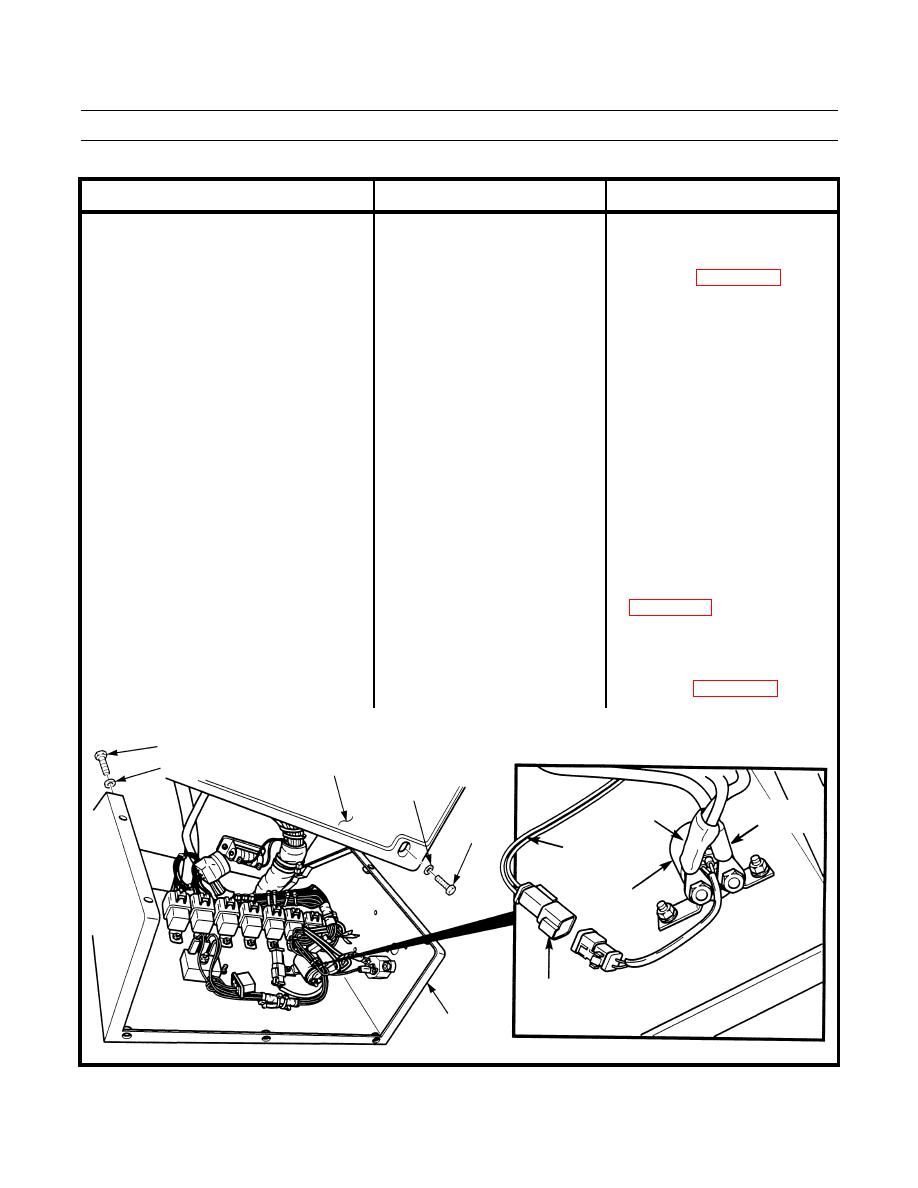

Remove nine screws and washers

replace or repair wire 109-OR and

and remove panel from operator

connectors (WP 0108 00).

station. Touch positive (+) probe

of multimeter to input terminal 2. If 24 to 28 Vdc are measured at

input terminal (wire 109-OR), go

(wire 109-OR) and negative (-)

to Step 2.

probe of multimeter to good

ground.

2. Check power to coil of main 1. If 24 to 28 Vdc are not measured

relay. Disconnect main relay

at terminal 1 (wire 308-YL) and

connector

from

harness

KEY START fuse is good, turn

connector. Turn engine start

engine start switch off and go to

switch to ON position (TM 5-

Step 4.

3895-379-10). Touch positive (+)

probe of multimeter to (wire 308- 2. If 24 to 28 Vdc are measured at

terminal 1, go to Step 3.

YL) and negative (-) probe of

multimeter to good ground.

3. Check main relay output. 1. If 24 to 28 Vdc are not measured

Connect main relay connector to

at output terminal of main relay

harness connector. Turn engine

(wire 112-PU), replace main relay

start switch to ON position (TM

5-3895-379-10). Touch positive

(+) probe of multimeter to output 2. If 24 to 28 Vdc are measured at

output terminal of main relay,

terminal of main relay (wire 112-

replace or repair wire 112-PU and

PU) and negative (-) probe of

connectors (WP 0108 00) to fuses.

multimeter to good ground.

SCREW

PANEL

ASSEMBLY

WASHER

WASHER

WIRE

WIRE

112-PU

109-OR

SCREW

WIRE 308-YL

MAIN

RELAY

HARNESS

CONNECTOR

OPERATOR

STATION

401-218