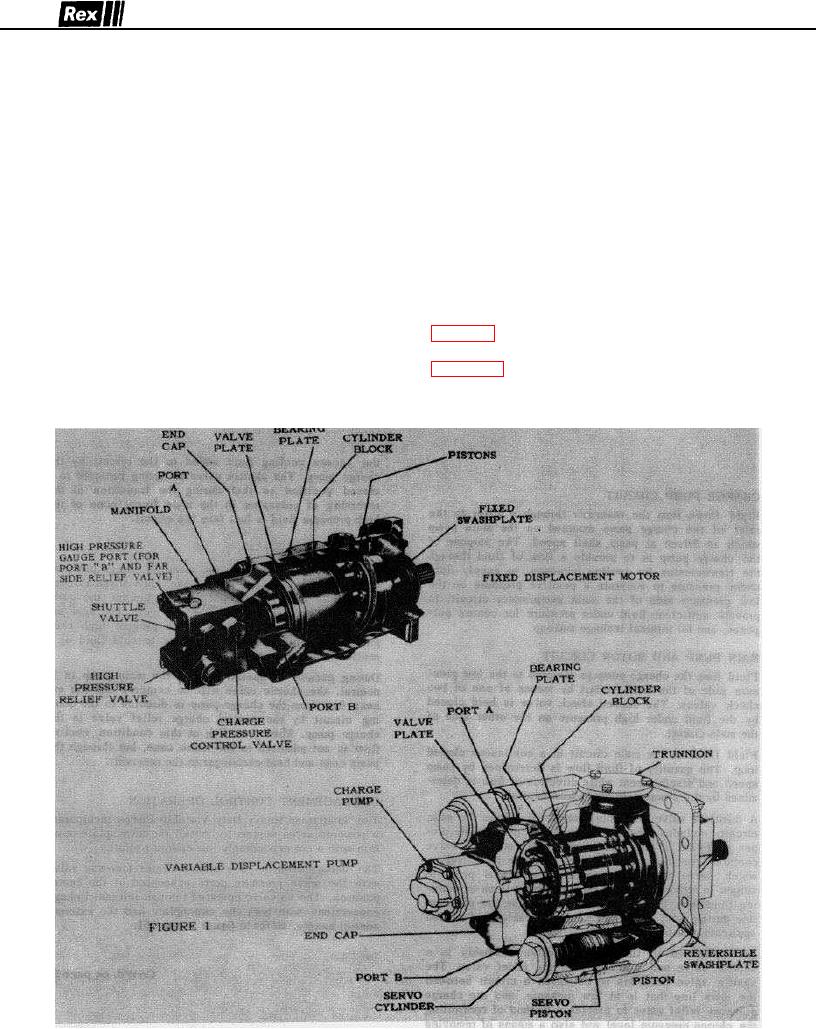

SUNDSTRAND (VARIABLE DISPLACEMENT HYDROSTATIC PUMP) AND (FIXED DISPLACEMENT

HYDROSTATIC MOTOR), PAGES 49 THRU 61.

HYDRAULIC CIRCUITS

the pump to the displacement of the motor will

determine the speed of the motor output shaft. Moving

GENERAL

the control lever to the opposite side of neutral, the flow

The hydrostatic transmission offers an infinite control of

from the pump is reversed and the motor output shaft

speed and direction. The operator has complete control

turns in the opposite direction. Speed of the output

of the system with one lever for speed and direction.

shaft is controlled by adjusting the displacement (flow)

of the pump.

Control of the variable displacement, axial piston pump

The pump and motor are contained in separate

is the key to controlling the roller. Engine horsepower is

housings. All valves required for a closed loop circuit

transmitted to the pump. When the operator moves the

are included in either the pump or motor assemblies. A

control lever, the swashplate in the pump is tilted from

reservoir, filter, cooler and lines complete the circuit.

neutral.

Figure 1 illustrates the internal components of a typical

When the variable pump swashplate is tilted, a positive

Sundstrand heavy duty hydrostatic transmission.

stroke to the pistons is created. This, in turn, at any

Figure 2 illustrates the general appearance of the

given input speed, produces a certain flow of oil from

components of a heavy duty transmission.

the pump. This flow is transferred through high pressure

lines to the motor. The ratio of the volume of flow from

FIGURE 1