pressure relief valves located in the motor manifold.

TROUBLE SHOOTING PROCEDURE

The relief valves have a two (2) digit number stamped

Before Proceeding With Trouble Shooting, Read the

on the exposed end stating valve setting (i.e. "50" =

Following Information!

5000 psi). High pressure gauge port (Gauge "B", figure

Sundstrand Heavy Duty transmissions must maintain

11) monitors far side high pressure' loop' and near side

various pressures to function properly. Any disturbance

relief valve.

of the proper pressure levels will lead to an inoperable

transmission.

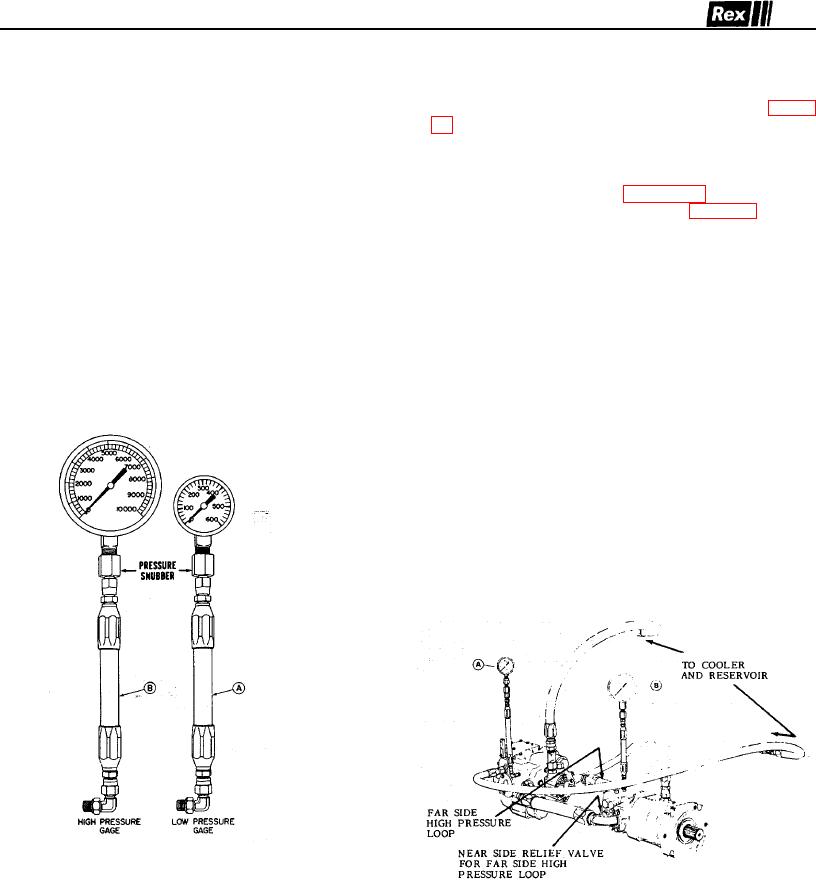

The necessary gauges and complimentary equipment

required are depicted in Figure 10. Their proper

1. CHARGE PRESSURE: The minimum allowable

installation in the circuit is depicted in Figure 11.

charge pressure is 130 p.s.i. Normal charge pressure is

160 p.s.i. and 190 p.s.i. when pump is in neutral.

NOTE: For accurate gauge interpretation, it is

recommended that the pump drive shaft be turning at or

near

2. SYSTEM OR HIGH PRESSURE: The maximum

maximum RPM.

system pressure obtainable is controlled by the high

A. Gauge Connection = 7/16 x 20 SAE "O" Ring -

All Series

B. Gauge Connection = 7/16 x 20 SAE "O" Ring -

All Series

TROUBLE SHOOTING GAUGES

FIGURE 10

TYPICAL GAUGE INSTALLATION (PV-MF)

FIGURE 11

44