DETROIT DIESEL 53

3.0

SHOP NOTES - TROUBLE SHOOTING - SPECIFICATIONS - SERVICE TOOLS

SHOP NOTES

REWORKING BLOWER END PLATES FOR IN-LINE ENGINES

On non-turbocharged engines built prior to serial number 3D-34008 when oil is detected on the blower rotors or inside

surface of the housing, the blower end plate can be reworked to accommodate a new lip type oil seal or a steel insert.

NOTE: Slight phonographic grooves can actually improve sealing. Unless wear is considerable and oil leakage is

evident, the end plate need not be reworked.

Rework Blower End Plate

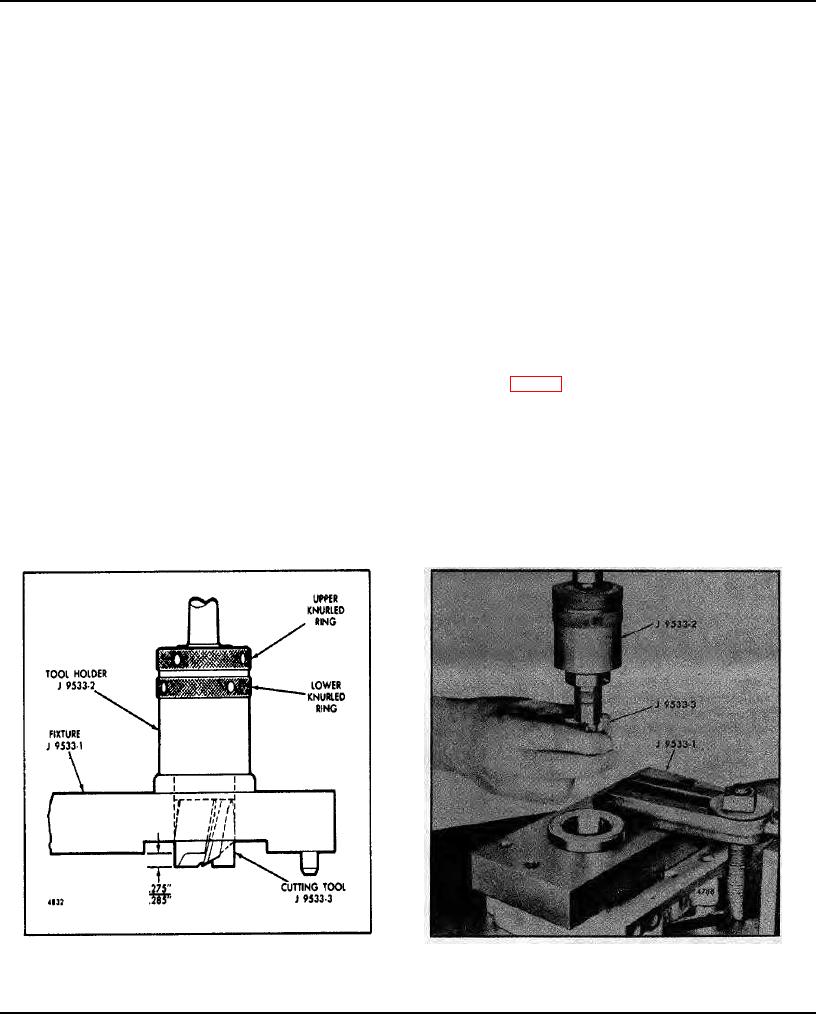

Use tool kit J 9533 to rework the end plate.

NOTE: On some prior serviced blowers, the end plates may have been reworked to accommodate a steel insert.

In such cases, proceed as follows but omit Step 10.

1.

Adjust the tool holder J 9533-2 and cutting tool J 9533-3 for the proper counterbore depth as follows:

a.

Insert the rough cutting tool J 9533-3 in the tool holder as shown in Fig. 1.

b.

Position the holder and the cutting tool in the fixture J 9533-1.

c.

Loosen the "upper knurled ring" -on the tool holder.

d.

Rotate the "lower knurled ring" to raise or lower the cutting tool. Turn the "lower knurled ring" until there is a

distance of .275 " - .285 " between the end of the cutting tool and the bottom of the fixture.

e.

Tighten the "upper knurled ring".

2.

Place fixture J 9533-1 on the blower end plate.

3. Clamp the fixture and the end plate loosely to the bed of a drill press.

Fig. 1 - Adjustment of Tool Holder

Fig. 2 Install Cutting Tool in Holder

March, 1973 SEC. 3.0 Page 1