SECTION 7

TRANSMISSION

c. Start the engine and increase speed to 1500

high-pressure oil.

RPM. The gauge should indicate 190 to 220 PSI (13.36

to 15.47 kg/cm2) above case pressure with oil at

7-154. LOW-CHARGE-PRESSURE RELIEF VALVE.

operating temperature. If. the pressure is not within the

7-155. The low-charge-pressure relief valve works with

specified limits, troubleshoot the system as specified in

the shuttle valve to control pressure in the charge circuit

and to remove excess oil to the cooling circuit. This

valve will allow additional oil to dump if the high-

7-160. CHECKING LOW CHARGE PRESSURE

pressure relief valves cannot dump fast enough under

excessive conditions. Excess oil will be ported through

(see figure 7-38).

the drain circuit to the oil cooler. It is operative only

7-161. The low charge pressure should be between 150

when the transmission is not in neutral.

and 180 PSI (10.55 and 12.66 kg/cm2) above case

pressure with oil at operating temperature, when the

transmission is operating in forward or reverse. The low

7-156. PRESSURE CHECKS.

charge pressure relief valve is located in the motor

7-157.

Pressure

checks

are

imperative

in

manifold as shown in figure 7-38. Check the pressure as

troubleshooting the hydraulic system.

follows:

a. Remove the threaded plug from the Low Charge

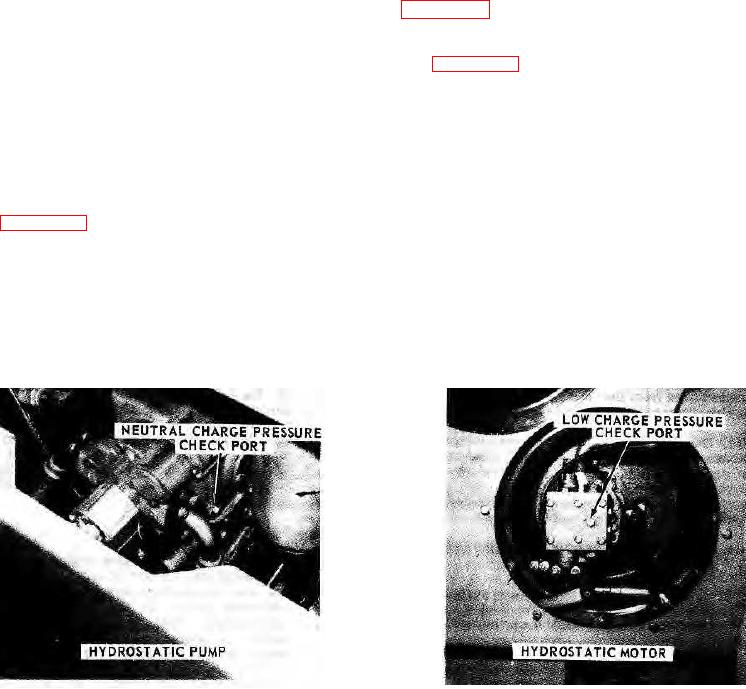

7-158. CHECKING NEUTRAL CHARGE PRESSURE

Pressure Check Port. Install a 600 PSI (40 kg/cm2)

(see figure 7-37).

gauge equipped with a short section of hose. Use an o-

7-159. Neutral charge pressure can be checked at the

ring adapter in the port. Make sure that the gauge is

transmission pump as follows:

accurately calibrated.

a. Remove the threaded plug from the charge

b. Block the drive drum safely off the ground and

pressure port. Install a 600 PSI (40 kg/cm2) gauge

start the engine.

equipped with a short section of hose. Make sure the

c. Increase engine speed to 1500 RPM. Move the

gauge is accurately calibrated.

Direction-Throttle Control Bail slightly to

NOTE: Use a 7/16 x 20 o-ring adapter in the port.

b. Place the Direction-Throttle Control Bail in

neutral.

FIGURE 7-37.

FIGURE 7-38.

7-30.