2.1.4

Injector Tube

DETROIT DIESEL 53

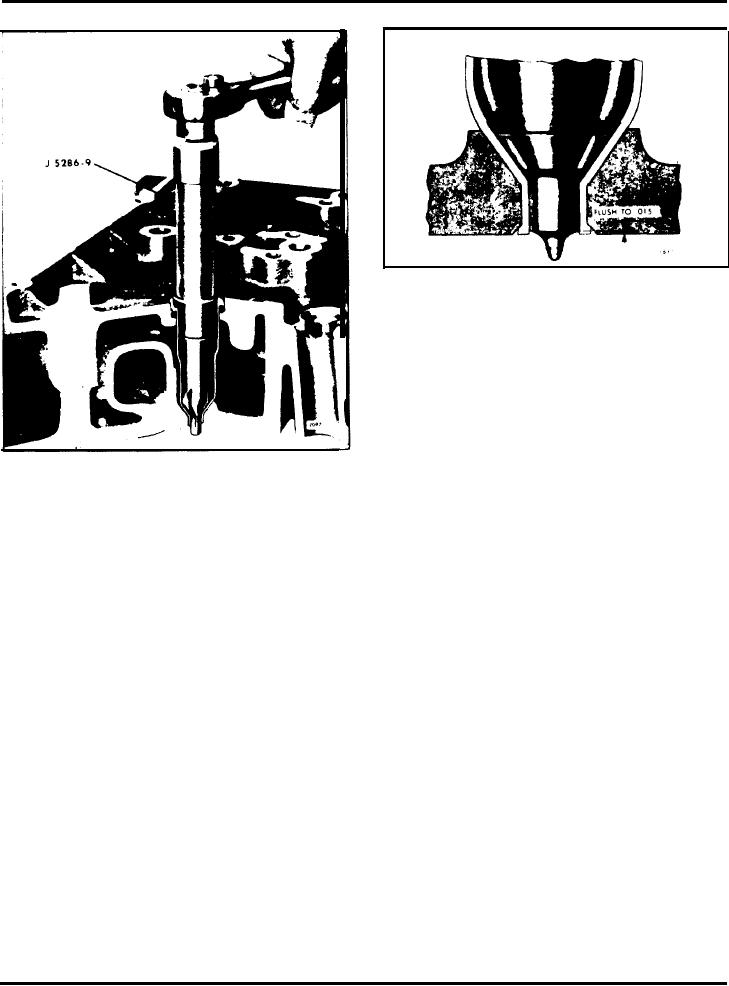

Fig. 6 - Checking Location of Injector Spray

Tip Relative to Lower Surface of Cylinder Head

injector tube with trichlomethylene or clean fuel oil

and dry it with compressed air. Then perform the

second reaming operation as follows:

a. Place a few drops of cutting oil on the bevel seat

of the tube. Carefully lower the reamer J 5286-9

into the injector tube until it contacts the bevel

seat.

b. Make a trial cut by turning the reamer steadily

Fig. 5 - Reaming Injector Tube for Injector Nut

without applying any downward force on the

3. Ream the bevel seat in the injector tube:

reamer. Remove the reamer, blow out the chips

and look at the bevel seat to see what portion of

The tapered lower end of the injector tube must

the seat has been cut.

provide a smooth and true seat for the lower end of

c. Proceed carefully with the reaming operation,

the injector nut to effectively seal the cylinder

withdrawing the reamer occasionally to observe

pressures and properly position the injector tip in the

the reaming progress.

combustion chamber. Therefore, to determine the

amount of stock that must be reamed from the bevel

d. Remove the chips from the injector tube and,

seat of the tube, the injector assembly should be

using an injector as a gage, continue the reaming

installed in the tube and the relationship between the

operation until the shoulder of the spray tip is

numbered surface of the spray tip to the fire deck of

within the limits specified in Fig. 6. Then wash

the cylinder head noted (Fig. 6).

the interior of the injector tube with trichloroeth-

ylene or clean fuel oil and dry it with compressed

With the first reaming operation completed and the

injector tube spot-faced, wash the interior of the

air.

SEC. 2.1.4 Page 3

November, 1973