DETROIT DIESEL 53

1.7.7 Accessory Drive

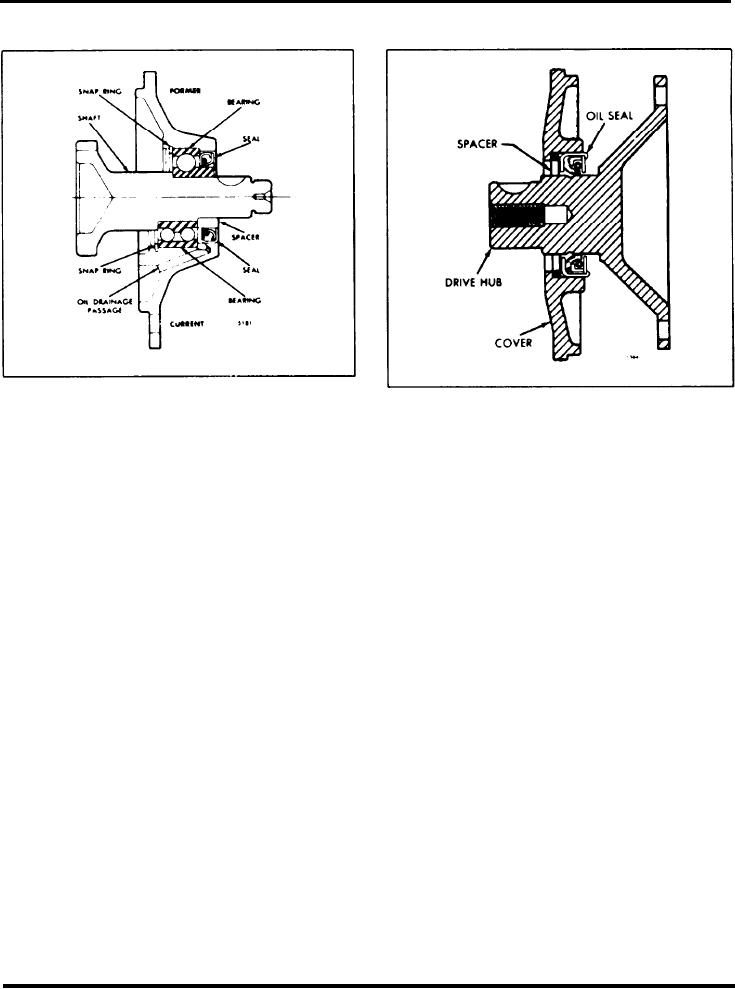

Fig. 7 Former and Current Drive Plate Type

Fig. 8 Location of Oil Seal Spacer

Accessory Drive

CAUTION: When replacing the drive hub on the

from the bearing. Wipe the outside of the bearing

accessory shaft. drive the hub squarely on the

clean. then hold the inner race and revolve the outer

shaft (refer to Section 12.4).

race slowly by hand. If the bearing is worn or does not

roll freely. replace the hearing.

a. Place a new gasket on the flange and align the

holes in the gasket with the bolt holes in the

Inspect the accessory drive hub. shown in Fig. 5, for

flange. Use a light coat of grease to retain the

grooving at the area of contact with the lip of the oil

gasket in position.

seal. If the hub is grooved to a point where the

effectiveness of the oil seal IS lost, a ring type oil seal

b. Place the accessory in position against the flywheel

spacer is available which serves to reposition the seal,

housing, rotating it. if necessary. IO align the teeth

thus providing a new sealing surface for the lip of the

of the accessory hub with those in the drive

seal (Fig. 8).

coupling. Secure the accessory to the flywheel

housing with five bolts and lock washers.

Install Accessory Drive

4. If the accessory drive shown in Figs. 6 or 7 is used.

assemble as follows:

1. Remove old gasket material from the flywheel

housing. Use care so that no gasket material falls into

a. Install the accessory drive plate and spacer as

the gear train compartment.

outlined in Steps 1 and 2 above.

2. Insert a clean, lintless cloth in the flywheel housing

b. Place the drive shaft retainer on the bed of an

opening to prevent bolts from accidentally falling in

arbor press, with the mounting flange side up.

the gear train. Align the bolt holes in the accessory

Press the double row ball bearing straight in until

drive plate and spacer (if used), or the accessory drive

the bearing contacts the shoulder in the bore of

hub. with the tapped holes in the camshaft or balance

the retainer. Install the snap ring.

shaft gear. Then secure the plate and spacer, or drive

hub. with four bolts (and lock washers or lock wire, if

NOTE: On former accessory drives (Fig. 7).

used). Remove the cloth from the flywheel housing

install the bearing with the protruding face of

opening.

the inner race towards the retainer.

3. If a gear driven accessory is used as shown in

c. Turn the retainer over and press the oil seal into

Figs. 3 and 4. install the accessory drive coupling,

the bore of the retainer with the lip of the seal

toward the bearing.

then:

Page 4