DETROIT DIESEL 53

1.3.7 Crankshaft Pulley

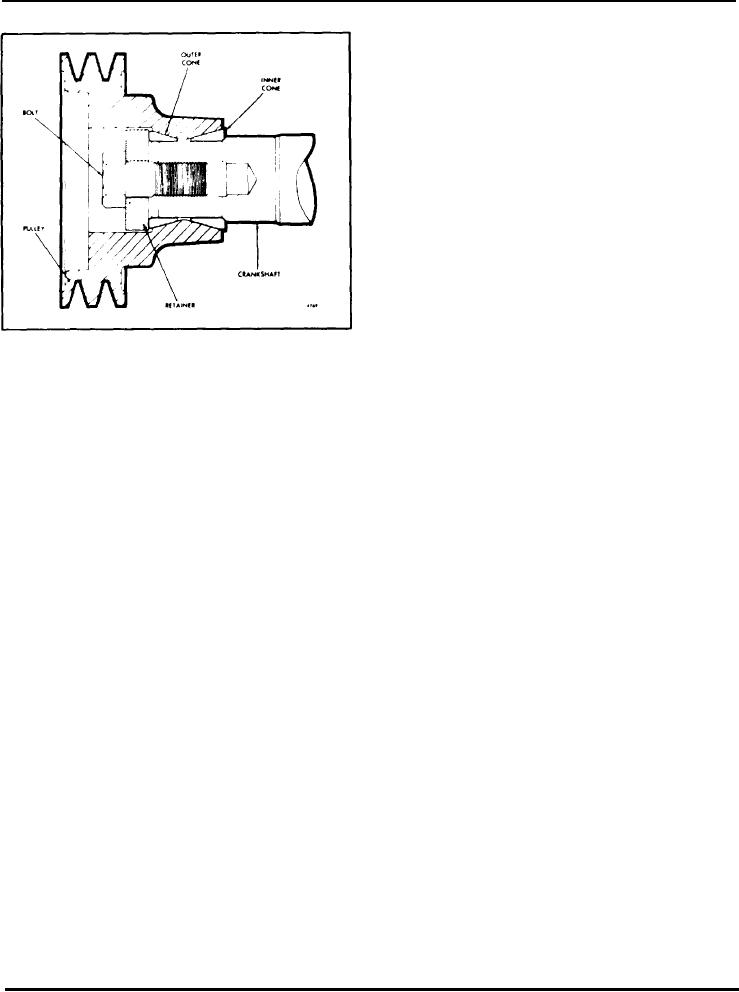

7 Slide the outer cone (Fig. 3). if used, on the

crankshaft.

8. Place the washer on the crankshaft bolt and thread

the bolt into the front end of the crankshaft.

10. On in-line engines with cone mounted pulleys

NOT stamped with the letter "A". tighten the 3/4 "-16

bolt to 290-300 lb-ft torque.

11. On all in-line

engines with the rigid type

pulleys and cone mounted pulleys stamped with the

letter "A". tighten the 3/4 "-16 bolt to 200-220 lb-ft

Fig. 3 Cone Mounted Pulley

torque.

engine

5. Install a rigid type pulley on an In-line

12. When pulleys stamped with the letter "U" (in a

with installer J 7773 as shown in Fig. 2. Then remove

square box) are used, tighten the 3/4"-l6 bolt to 290-

the installer.

310 lb-ft torque.

14. Install and adjust the belts

Page 2