DETROIT DIESEL

cooler. From the cooler the flow is the same as in the

Keel Cooling System

other systems. Upon leaving the thermostat housing,

the coolant is by-passed directly to the bottom of the

The keel cooling system is similar to the heat

expansion tank until the engine operating tempera-

exchanger system, except that the coolant temperature

ture, controlled by the thermostat, is reached. As the

is reduced in the keel cooler. In this system, the

engine temperature increases, the coolant is directed to

coolant is drawn by the circulating pump from the

the keel cooler, where the temperature of the coolant is

bottom of the expansion tank through the engine oil

reduced before flowing back to the expansion tank.

ENGINE COOLING SYSTEM MAINTENANCE

S t a r t the engine and, after normal operating

Engine Coolant

temperature has been reached, allowing the coolant to

expand to its maximum, check the coolant level. The

The function of the engine coolant is to absorb the

coolant level should be within 2" of the top of the

heat, developed as a result of the combustion process

filler neck.

in the cylinders, from the component parts such as

Should a daily loss of coolant be observed, and there

surrounded by water jackets. In addition, the heat

are no apparent leaks, there is a possibility of gases

absorbed by the oil is also removed by the engine

leaking past the cylinder head water seal rings into the

coolant in the oil-to-water oil cooler.

cooling system. The presence of air or gases in the

cooling system may be detected by connecting a

For the recommended coolant, refer to Engine Coolant.

rubber tube from the overflow pipe to a water

container. Bubbles in the water in the container during

engine operation will indicate this leakage. Another

Cooling System Capacity

method for observing air in the cooling system is by

inserting a transparent tube in the water outlet line.

The capacity of the basic engine cooling system

(cylinder block, head, thermostat housing and oil

cooler housing) is shown in Table 1.

Drain Cooling System

To obtain the complete amount of coolant in the

The engine coolant is drained by opening the cylinder

cooling system of an engine, the additional capacity of

block and radiator (heat exchanger) drain cocks and

the radiator, hoses, etc. must be added to the capacity

removing the cooling system filler cap. Removal of the

of the basic engine. The capacity of radiators and

filler cap permits air to enter the cooling passages and

related equipment should be obtained from the

the coolant to drain completely from the system.

equipment supplier.

Drain cocks or plugs are located on each side of the

4-53 and 6V cylinder blocks. The 3-53 cylinder block

has a drain cock or plug located on the side of the

Fill Cooling System

block opposite the oil cooler.

Before starting an engine, close all of the drain cocks

IMPORTANT: Drain cocks or plugs on both sides

and fill the cooling system completely. If the unit has a

of the engine must be opened to drain the

raw water pump, it should be primed, since operation

engine completely.

without water may cause impeller failure.

In addition to the drains on the cylinder blocks, the In-

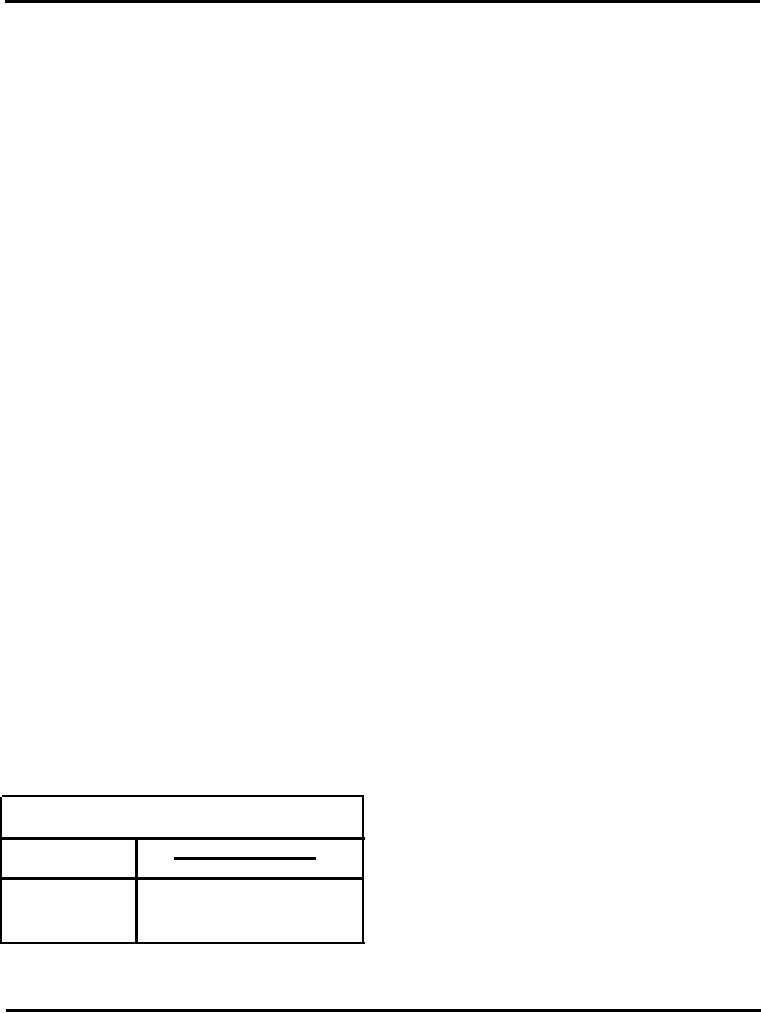

COOLING SYSTEM CAPACITY CHART

line engines have a drain cock located on the bottom

(BASIC ENGINE)

of the oil cooler housing. The V-type engines have two

drain cocks that must be opened when draining the

CAPACITY

ENGINE

system. Radiators, etc., that do not have a drain cock,

Quarts

Litres

are drained through the oil cooler housing drain.

3-53

-8

8

9

9

4-53

To insure that all of the coolant is drained completely

6V-53

14

13

from an engine, all cooling system drains should be

opened. Should any entrapped water in the cylinder

block or radiator freeze, it will expand and may cause

TABLE 1

damage. When freezing weather is expected, drain all

engines not adequately protected by antifreeze. Leave

Page 27