TM 5-3895-346-14

INSTRUMENTS

ENGINE OVERHAUL

full length with suitable clips at intervals of ten inches or less. Sharp bends in the tube must be avoided,

particularly at the gage or bulb connection areas. Where the tube must be bent around any object, the bend

must not be less than one inch radius.

Any extra length can be taken up by coiling, the diameter of which should not be less than two inches. The

coils must be located so that they may be securely fastened to prevent vibrating.

The ammeter is wired into the electrical circuit to show the current flow to and from the battery. After starting

the engine, the ammeter should register a high charge rate at rated engine speed. This is the rate of charge

received by the battery to replenish the current used to start the engine. As the engine continues to operate,

the ammeter should show a decline in the charge rate to the battery. The ammeter will not show zero charge

rate since the regulator voltage is set higher than the battery voltage. The small current registered prevents

rapid brush wear in the battery-charging alternator. If lights or other electrical equipment are connected into the

circuit, then the ammeter will show discharge when these items are operating and the engine speed is reduced.

The tachometer, driven by the engine, registers the speed of the engine in revolutions per minute (rpm).

Throttle Control

The engine throttle is connected to the governor speed control shaft through linkage. Movement of the speed

control shaft changes the speed setting of the governor and thus the engine speed.

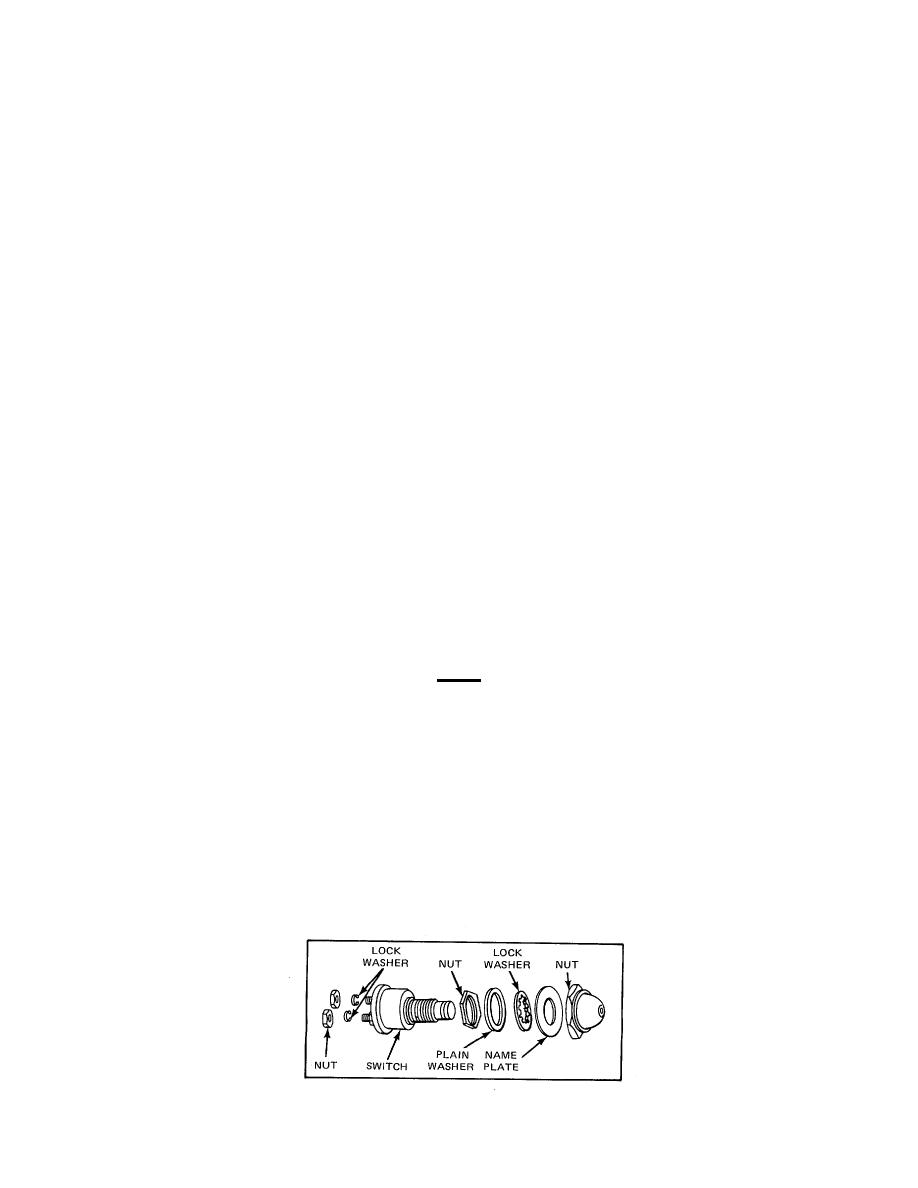

Engine Starting Switch

To start the engine, a switch (Fig. 2) is used to energize the starting motor. Starting switches may vary in

design and their contacts must be rated sufficiently to carry the starter solenoid current.

NOTE

Tighten the starting-switch mounting nut to 36-48 lb in. (4-5.5 Nm).

Engine Stop Knob

A stop knob is used to stop the engine. When stopping an engine, the engine speed should be reduced to idle

and the engine allowed to operate at idle for a few minutes to permit the coolant to reduce the temperature of

the engine's moving parts. Then pull the stop knob and hold it until the engine stops. Pulling on the stop knob

manually places the injector racks in the no-fuel position. Return the stop knob to its original position after the

engine stops.

Emergency Stop Knob

In an emergency, or if the engine continues to operate after pulling the stop knob, the emergency stop knob

may be used to stop the engine. When the emergency stop knob is pulled, the air

Figure 2. Typical Engine Starting Switch

381