TM 5-3895-346-14

STARTING MOTOR

ENGINE OVERHAUL

STARTING MOTOR

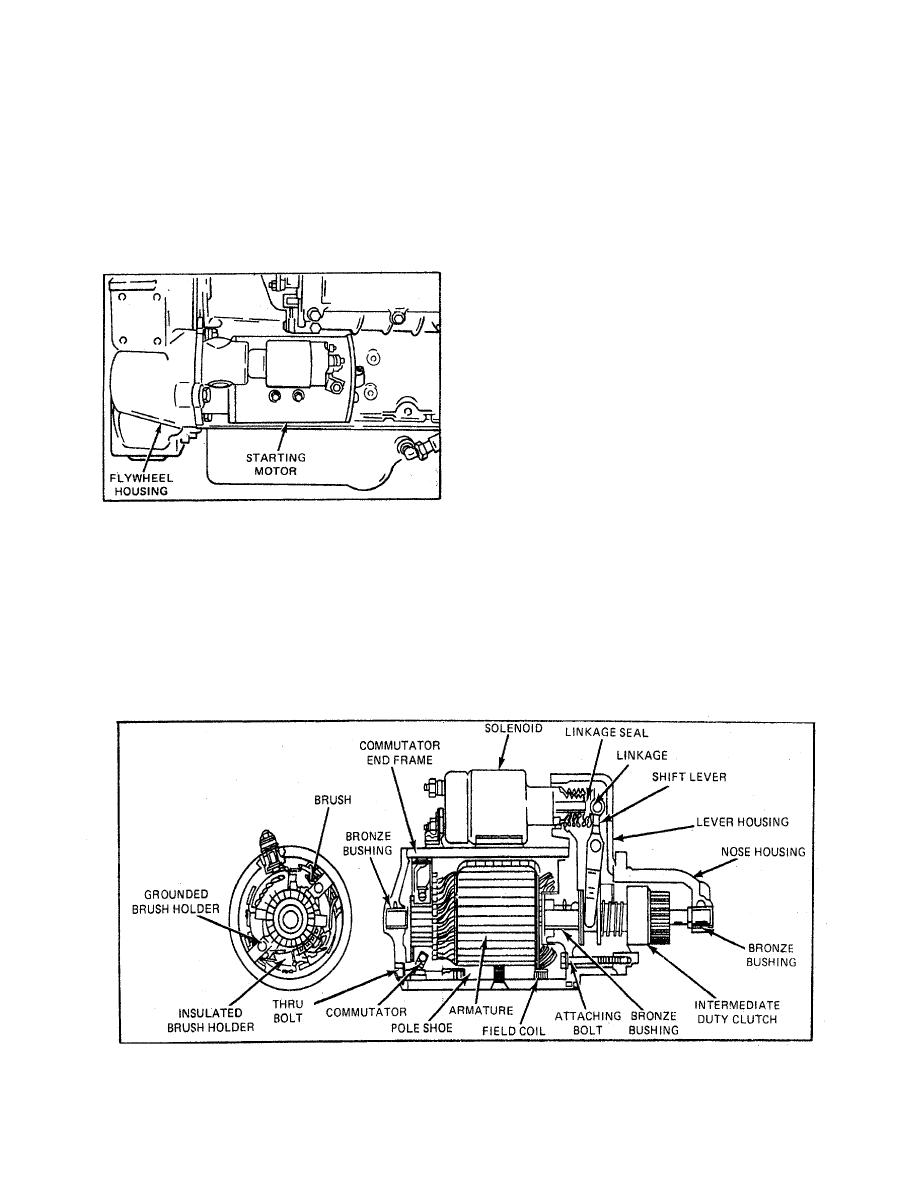

The starting motor is mounted on the flywheel housing as illustrated in Fig. 1. When the starting circuit is

closed, a small drive pinion on the armature shaft engages with the teeth on the engine flywheel ring gear to

crank the engine. When the engine starts, it is necessary to disengage the drive pinion to prevent the armature

from over speeding and damaging the starting motor. To accomplish this, the starting motor is equipped with a

Sprag-type overrunning clutch.

A solenoid switch, mounted on the starting motor

housing, operates the Sprag-type overrunning clutch

drive by linkage and a shift lever (Fig 2).

When the starting switch is engaged, the solenoid is

eneirgi2ed and shifts the starting motor pinion into

mesh with the: flywheel ring gear and closes the main

contacts within the solenoid. Once engaged, the clutch

will not disengage during intermittent engine firing. To

protect the armature from excessive speed when the

engine starts, the clutch overrules, or turns faster than

the armature, which permits the pinion to disengage

itself from the flywheel ring gear.

The solenoid plunger and shift lever is totally enclosed

Figure 1. Starting Motor Mounting

to protect them from dirt, water, and other foreign

material.

The nose housing an the Sprag clutch-type starting motor can be rotated to obtain a number of different

solenoid positions with respect to the mounting flange. When repositioning of the solenoid is required on a

service replacement starting motor, proceed as follows:

Starter with Intermediate-Duty Clutch (In-Line Engines)

The lever housing and the commutator end frame are held to the field frame by bolts extending from the end

frame

Figure 2 . Cross-Section of Motor with Intermediate-Duty Clutch

377