TM 5-3895-346-14

FUEL INJECTOR

ENGINE OVERHAUL

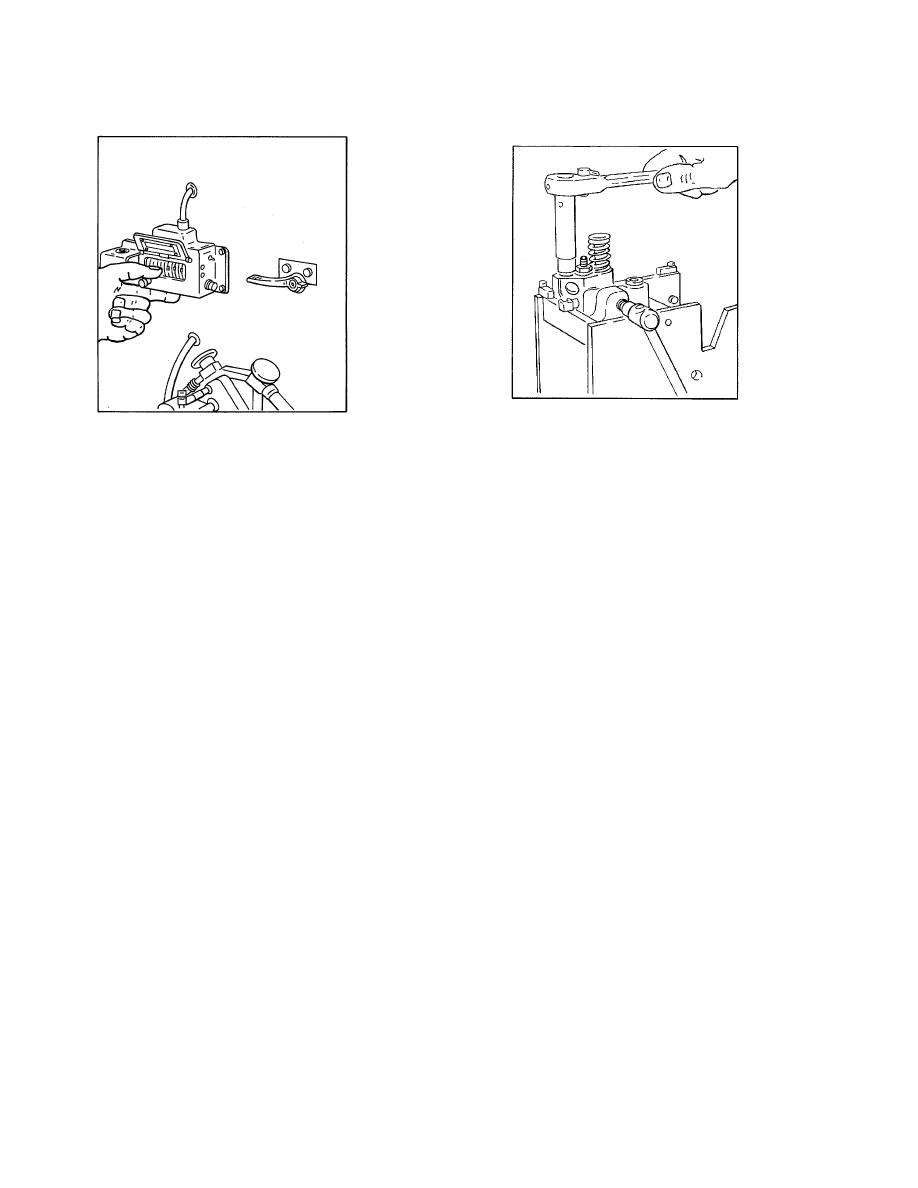

Figure 22. Setting Calibrator Stroke Counter.

Figure 23. Removing or Installing Filter Cap

An injector which passes all of the above tests may be put back into service. However, an injector which fails to

pass one or more of the tests must be rebuilt and checked on the calibrator.

Any injector which is disassembled and rebuilt must be tested again before being placed in service.

Disassemble Injector

If required, disassemble an injector as follows:

1. Support the injector upright in injector holding fixture J 22396 (Fig. 23) and remove the filter caps, gaskets,

and filters.

CAUTION

Whenever a fuel injector is disassembled, discard the filters and gaskets and replace with new

filters and gaskets.

In the offset injector, a filter is used in the inlet side only. No filter is required in the outlet side (Fig. 35).

2. Compress the follower spring as shown in Fig. 11. Then raise the spring above the stop pin with a screw-

driver and withdraw the pin. Allow the spring to rise gradually.

3. Refer to Fig. 24 and remove the plunger follower, plunger, and spring as an assembly.

4. Invert the fixture and, using socket J 4983-01, loosen the nut on the injector body (Fig. 25).

5. Lift the injector nut straight up, being careful not to dislodge the spray tip and valve parts. Remove the spray

tip and valve parts from the bushing and place them in a clean receptacle until ready for assembly.

226