TM 5-3895-346-14

FUEL INJECTOR

ENGINE OVERHAUL

plastic fuel outlet tube on the calibrator (Fig. 20)

depends on the adaptor being used and the

direction of fuel flow through the injector.

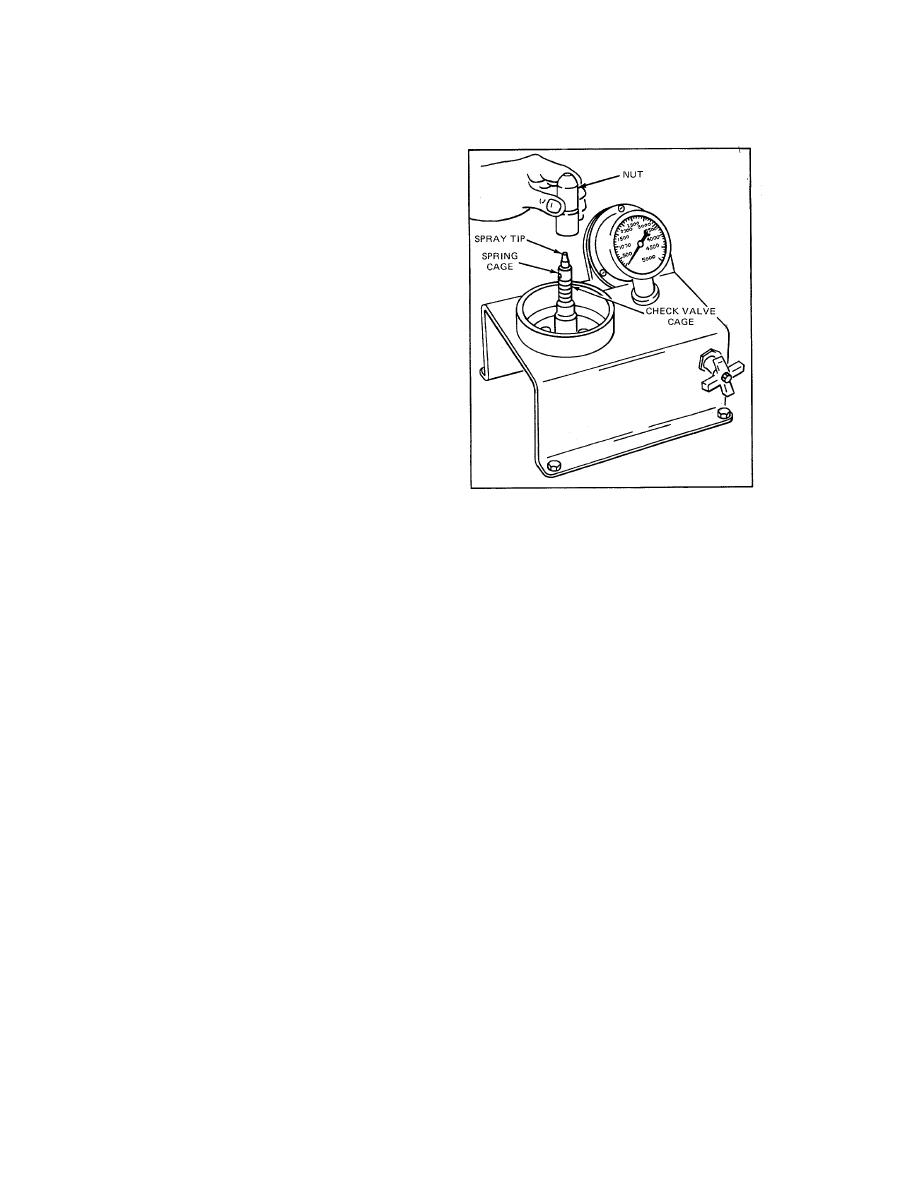

Calibrator J 22410

To check the fuel output, operate the injector in

calibrator J 22410 (Fig. 21) as follows:

NOTE

Place the cam shift index wheel and

fuel flow lever in their respective

positions. Turn on the test fuel oil

heater switch and preheat the test oil to

95- 105 (35-400C).

F

1. Place the proper injector adaptor between

the tie rods and engage it with the fuel block

locating pin. Then slide the adaptor forward and

up against the fuel block face.

2. Place injector seat J 22410-226 into the

Figure 18. Installing Injector Valve

permanent seat (cradle handle in vertical

parts on Auxiliary Tester J 22640

position). Clamp the in- jector into position by

operating the air valve.

NOTE

Make sure the counter (Fig. 22) on the calibrator is preset at 1000 strokes. If for any reason this

setting has been altered, reset the counter to 1000 strokes by twisting the cover release button to

the left and hold the reset lever in the full up position while setting the numbered wheels. Close

the cover. Refer to the calibrator instruction booklet for further information.

3. Pull the injector rack out to the no-fuel position.

4. Turn on the main power control circuit switch. Then start the calibrator by turning on the motor starter

switch.

NOTE

The low oil pressure warning buzzer will sound briefly until the lubricating oil reaches the proper

pressure.

5. After the calibrator has started, set the injector rack into the full-fuel position. Allow the injector to operate

for approximately 30 seconds to purge the air that may be in the system.

6. After the air is purged, press the fuel flow start button (red). This will start the flow of fuel into the vial. The

fuel flow to the vial will automatically stop after 1000 strokes.

7. Shut the calibrator off (the calibrator will stop in less time at full-fuel).

224