TM 5-3895-346-14

CAMSHAFT AND BEARINGS

ENGINE OVERHAUL

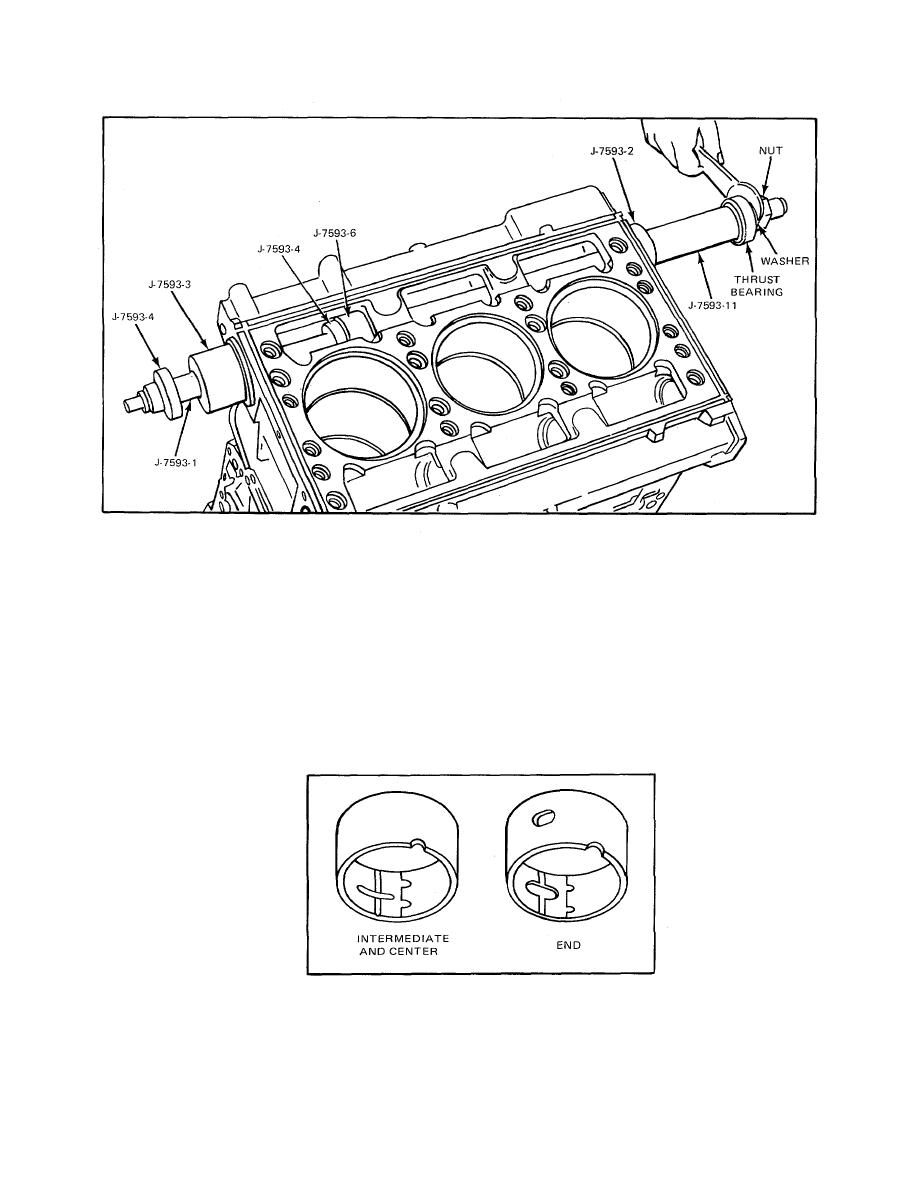

Figure 6. Installing Intermediate Camshaft Bearing

3. Then, with the unthreaded end of shaft J 7593-1 started through the pilot, push the shaft through the

entire length of the block bore.

4. Slide installer J 7593-6 on the shaft until the locating pin registers with the notch in the bearing. Then

slide installer J 7593-3 or J 7593-15 on the shaft with the large diameter inserted into the end of the block

bore. Refer to C and note of Fig. 9.

5. Next, place a spacer (if required), thrust washer, plain washer, and hex nut over the threaded end of

the puller.

6. Align the shaft in such a way that a C-washer J 7593-4 can be inserted in a groove in the shaft adja-

cent to installer J 7593-6.

Figure 7. Camshaft and Balance Shaft Bearing Identification

7. Place a C-washer in the groove near the end of the shaft and, using a suitable wrench on the hex nut,

draw the bearing into place until the Cwasher butts up against installer J 7593-3 and prevents the shaft from

further movement.

177