TM 5-3895-346-14

FLYWHEEL HOUSING

ENGINE OVERHAUL

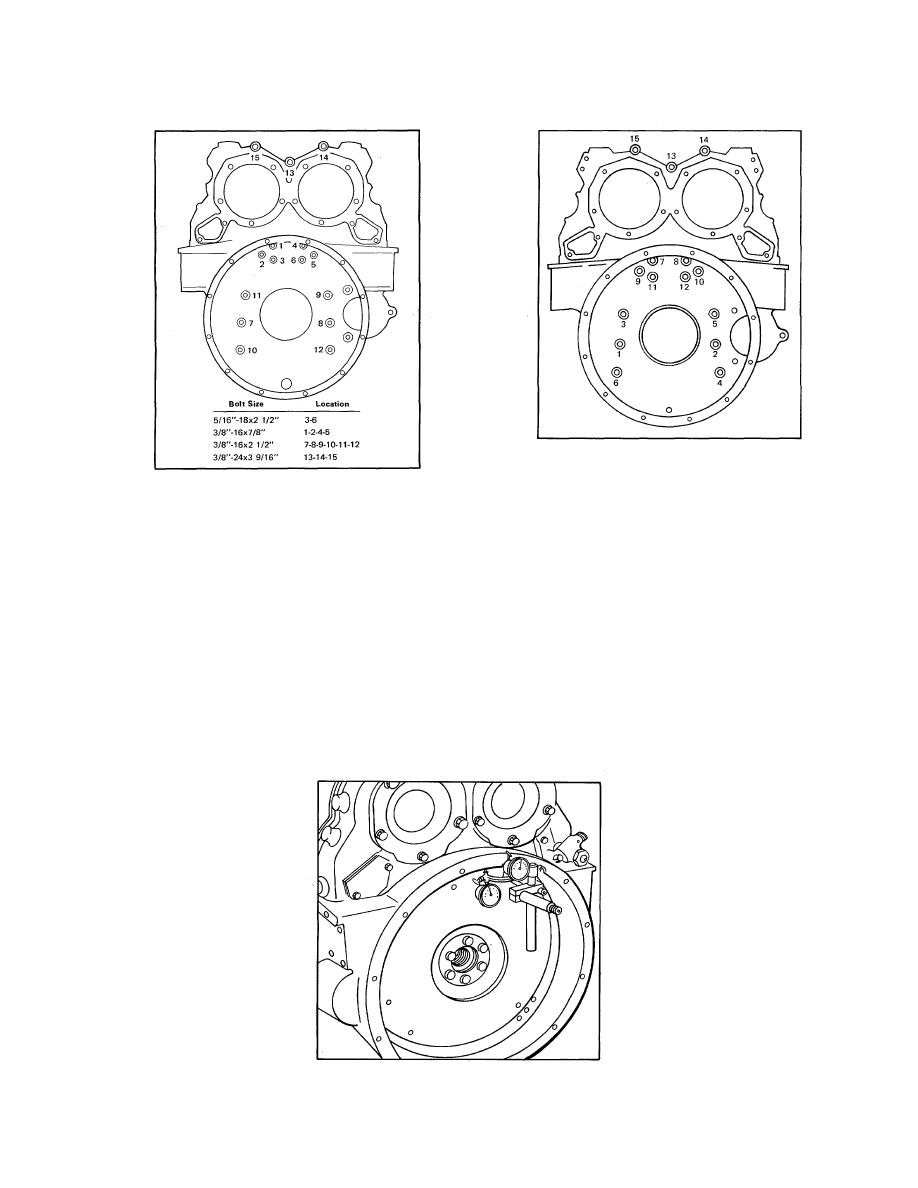

Figure 4. Flywheel Housing Bolt

Tightening Sequence (Operation

Figure 3. Flywheel Housing Bolt

2) - In-Line Engine

Sizes and Tightening Sequence

(Operation 1) - In-Line Engine

b.

On the two-, three-, and four cylinder engines, tighten the two 5/16-18 bolts that secure the top of

the governor to the flywheel housing to 10-12 lb ft (14-16 Nm) torque.

10.

Install the flywheel.

11.

Check the flywheel housing concentricity and bolting flange face with tool J 9737-01 as follows:

a.

Refer to Fig. 5 and thread the base post J 9737-3 tightly into one of the tapped holes in the

flywheel. Then assemble the dial indicators on the base post.

b.

Position the dial indicators straight and square with the flywheel housing bell face and inside

bore of the bell. Make sure each indicator has adequate travel in each direction.

Figure 5. Checking Flywheel

Housing Concentricity

137