TM 5-3895-346-14

MAIN BEARINGS

ENGINE OVERHAUL

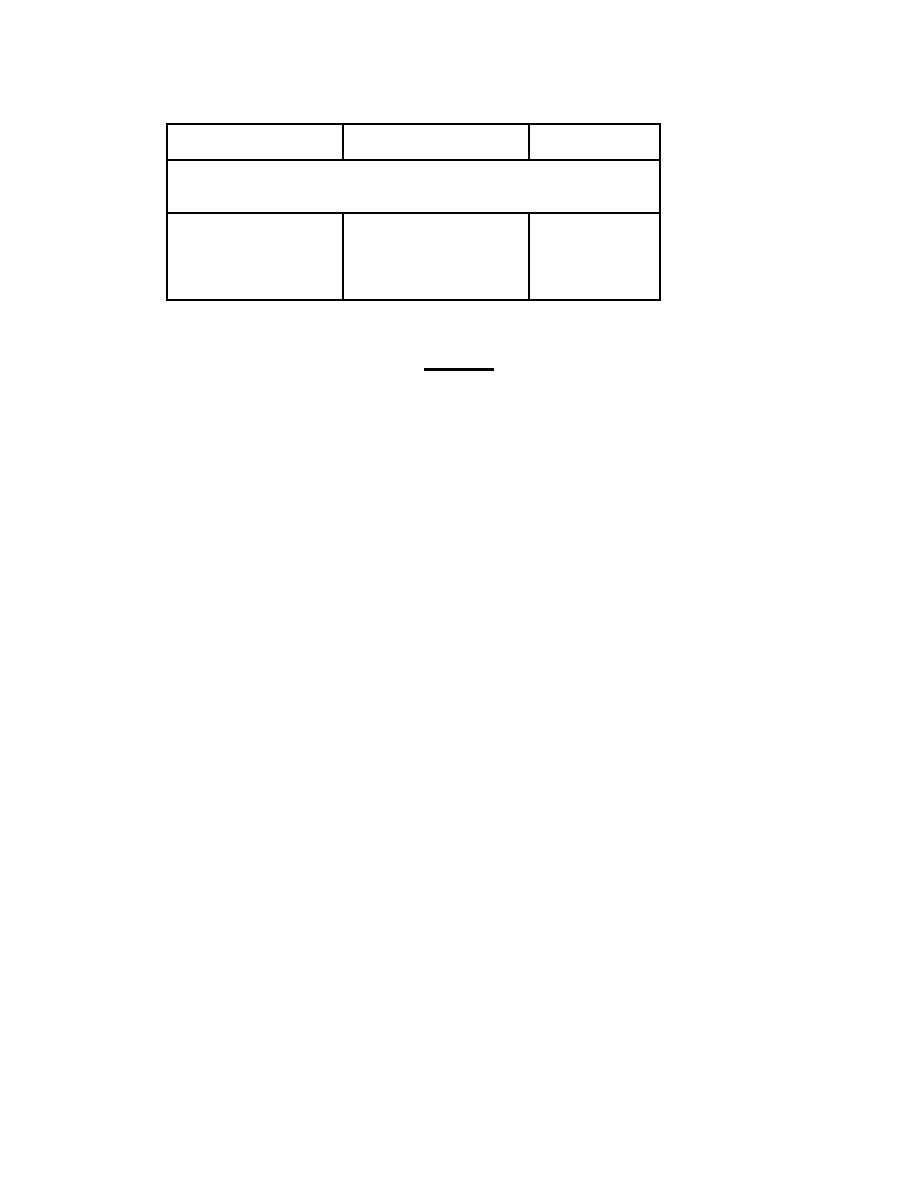

Bearing

Bearing

Minimum

Size

Thickness

Thickness

In-Line Engines

Standard

0.1245-0.1250 inch

0.1230 inch

0.002 inch Undersize

0.1255-0.1260 inch

0.1240 inch

0.010 inch Undersize

0.1295-0.1300 inch

0.1280 inch

0.020 inch Undersize

0.1345-0.1350 inch

0.1330 inch

0.030 inch Undersize

0.1395-0.1400 inch

0.1380 inch

TABLE 1

CAUTION

Bearing shells are NOT reworkable from one undersize to an- other under any

circumstances.

Inspect the crankshaft thrust washers. If the washers are scored or worn excessively or the crankshaft end play

is excessive, they must be replaced. Improper clutch adjustment can contribute to excessive wear on the thrust

washers. Inspect the crankshaft thrust surfaces. Refer to Install Crankshaft. If, after dressing or regrinding the

thrust surfaces, new standard size thrust washers do not hold the crankshaft end play within the specified limits,

it may be necessary to install oversize thrust washers on one or both sides of the rear main bearing. A new

standard size thrust washer is 0.1190 to 0.1220 inch thick. Thrust washers are available in 0.005 inch and 0.010

inch oversize.

Install Main Bearing Shells (Crankshaft in Place)

Make sure all of the parts are clean. Then apply clean engine oil to each crankshaft journal and install the

upper main bearing shells by reversing the sequence of operations given for removal.

The upper and lower main bearing shells are not alike: the upper bearing shell is grooved and drilled for

lubrication; the lower bearing shell is not. Be sure to install the grooved and drilled bearing shells in the cylinder

block and the plain bearing shells in the bearing caps, otherwise the oil flow to the bearings and to the upper

end of the connecting rods will be blocked off. Used bearing shells must be reinstalled on the same journal

from which they were removed.

1.

When installing an upper main bearing shell with the crankshaft in place, start the plain end of the

bearing shell around the crankshaft journal so that, when the bearing is in place, the tang will fit into the groove

in the bearing support.

2.

Install the lower main bearing shell so that the tang on the bearing fits into the groove in the

bearing cap.

3.

Assemble the crankshaft thrust washers (Fig. 7) before installing the rear main bearing cap. Clean

both halves of each thrust washer carefully and remove any burrs from the washer seats; the slightest burr or

particle of dirt may decrease the clearance between the washers and the crankshaft beyond the specified limit.

Slide the upper halves of the thrust washers into place. Then assemble the lower halves over the dowel pins in

the bearing cap.

123