TM 5-3895-346-14

CYLINDER BLOCK

ENGINE OVERHAUL

inch difference between any two adjacent cylinder counterbores when measured along the cylinder longitudinal

centerline of the cylinder block.

4.

Check the main bearing bores as follows:

a.

Check the bore diameters with the main bearing caps in their original positions. Lubricate the

bolt threads and bolt head contact areas with a small quantity of International Compound No. 2, or equivalent.

Then install and tighten the bolts to the specified torque. When making this check, do not install the main

bearing cap stabilizers. The specified bore diameter is 3.251 to 3.252 inches. If the bores do not fall within

these limits, the cylinder block must be rejected.

CAUTION

Main bearing cap bolts are especially designed for this purpose and must not be

replaced by ordinary bolts. Effective with engine serial numbers 6D-27030 and

8D-1155, a new hexagon head bolt and hardened steel washer are being used in

place of the former 12-point flange-type main bearing cap bolt.

CAUTION

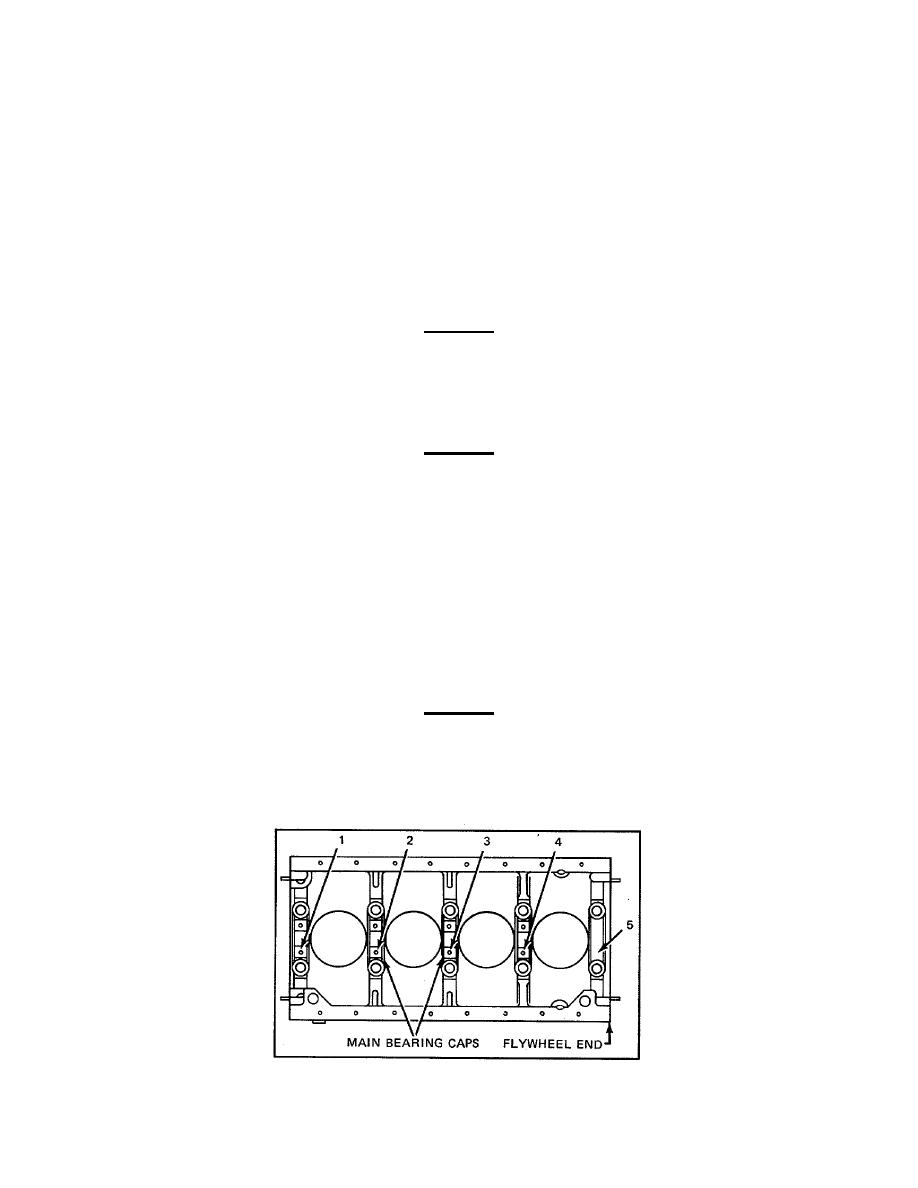

Bearing caps are numbered to correspond with their respective positions in the

cylinder block. It is imperative that the bearing caps are reinstalled in their original

positions to maintain the main bearing bore alignment. The number of the front

main bearing cap is also stamped on the face of the oil pan mounting flange of the

cylinder block, adjacent to its permanent location in the engine as established at

the time of manufacture. The No. 1 main bearing cap is always located at the end

opposite the flywheel end of the cylinder block (Fig. 11).

b.

Finished and unfinished main bearing caps are available for replacing broken or damaged

caps. When fitting a finished replacement bearing cap, it may be necessary to try several caps before one will

be found to provide the correct bore diameter and bore alignment. If a replacement bearing cap is installed, be

sure to stamp the correct bearing position number on the cap.

CAUTION

Use the unfinished bearing caps for the front and intermediate bearing positions. The finished bearing caps,

machined for the crankshaft thrust washers, are to be used in the rear bearing position.

c.

Main bearing bores are linebored with the bearing caps in place and thus are in longitudinal

alignment. Bearing bores may be considered properly aligned with one another if the crankshaft can be rotated

freely by hand after new bearing shells have been installed and lubricated, the bearing

Figure 11. Typical Cylinder Block Markings

64