TM 5-3895-346-14

CYLINDER BLOCK

ENGINE OVERHAUL

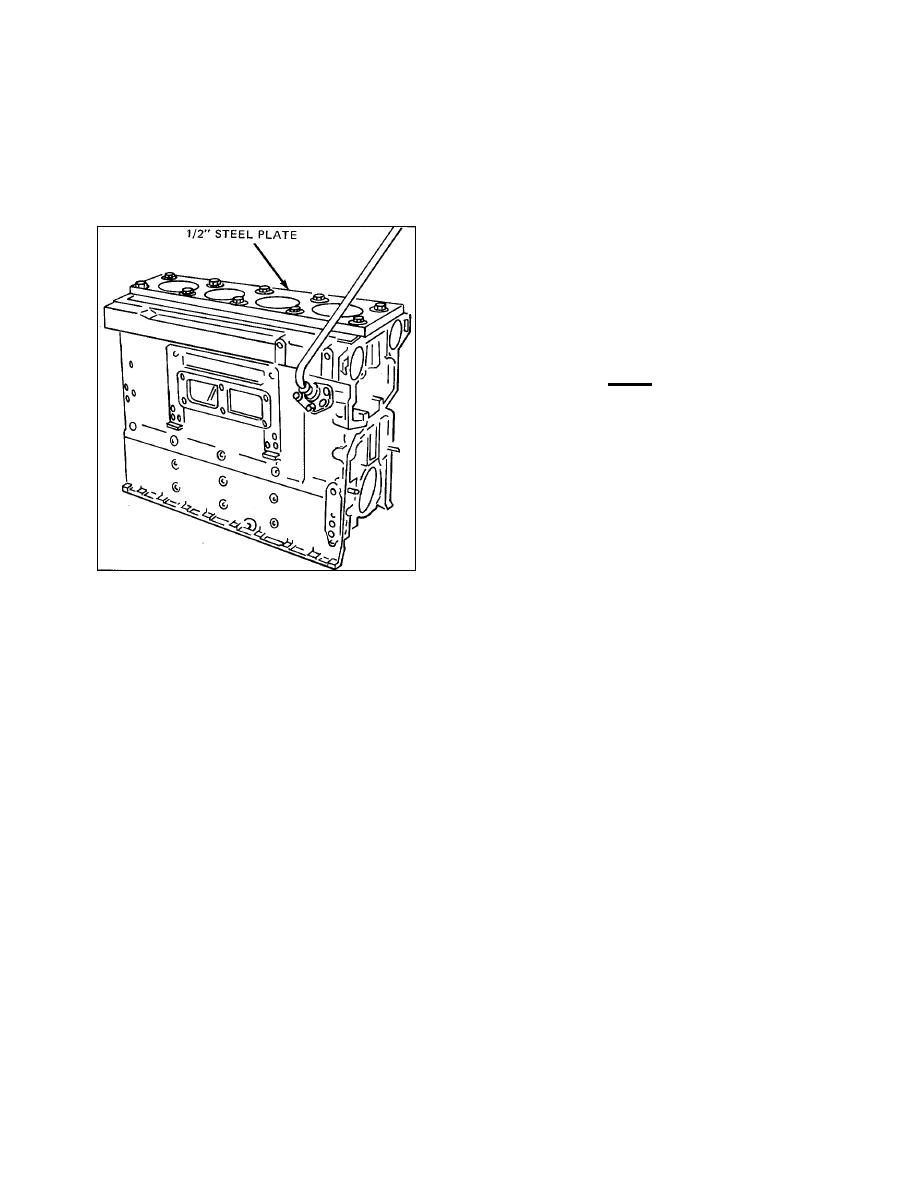

necessary to use water hole cover plates and gaskets to seal the water inlet openings in the sides of the block.

One cover plate should be drilled and tapped to provide a connection for an air line so the water jacket can be

pressurized.

METHOD A

This method may be used when a large enough water tank

is available and the cylinder block is completely stripped of

all parts.

1.

Make sure the seal ring grooves in the cylinder bores

of the block are clean. Then install new seal rings in the

grooves (above the air inlet ports).

NOTE

The current blocks have two

seal ring grooves above the air

inlet ports of each cylinder

bore. Only one seal ring is

required, however. Install the

seal ring in the upper groove, if

it is in good condition; if the

upper groove is pitted or

eroded, install the seal ring in

the lower groove.

2.

Apply a light coating of hydrogenated vegetable-type shortening or permanent-type antifreeze solution to

the seal rings.

3.

Slide the cylinder liners into the block, being careful not to roll or damage the seal rings. Install new

compression gaskets and water hole seal rings in the counterbores in the top surface of the block.

4.

Secure the plate(s) on the top of the block with 5/8-11 bolts and flat washers.

5.

Install the water hole cover plates and gaskets on the sides of the block.

6.

Immerse the cylinder block for twenty minutes in a tank of water heated to 180-200 (82-93 ).

F

C

7.

Attach an air line to the water hole cover plate and apply 40 psi (276 kPa) air pressure to the water

jackets and observe the water in the tank for bubbles which will indicate cracks or leaks. A cracked cylinder

block must be replaced by a new block.

8.

Remove the block from the water tank. Then remove the plates, seals, gaskets, and liners and blow out

all of the passages in the block with compressed air.

9.

Dry the cylinder liners with compressed air and coat them with oil to prevent rust.

61