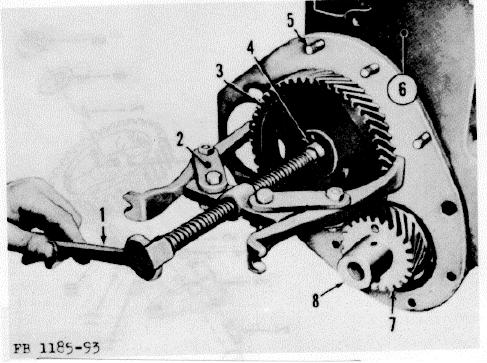

1

Wrench

5

Cover stud

2

Gear puller

6

Cylinder block

3

Camshaft gear

7

Crankshaft gear

4

Camshaft

8

Crankshaft

Figure 93. Camshaft gear removal.

damage the cam lobes and camshaft journals. Clean all threaded surfaces with a stiff wire brush and remove all sludge,

dirt, and corrosion from the threads.

d. Inspection.

(1) Alinement. Place the camshaft in V-blocks and install paper strips soaked in oil under the journals to

prevent scoring. Attach a dial indicator to the center journal and rotate the camshaft. Replace a camshaft

that is more than 0.003 inch out of line. Attach a dial indicator to the end journal and take a reading in the

same manner. Replace a camshaft that is more than 0.003 inch out of line.

(2) Journals. Measure each camshaft journal with a micrometer for wear. Replace a camshaft if the journals

are worn more than 0.002 inch.

(3) Bearings. Replace the bearings if they are worn, damaged, or scored. Insert a thickness gage not wider

than one quarter inch between the camshaft and the bearing. The proper clearance is 0.0015 to 0.0025

inch. If one or all of the bearings are worn 0.003 inch, a new set of bearings must be installed. Always

install bearings in sets.

227