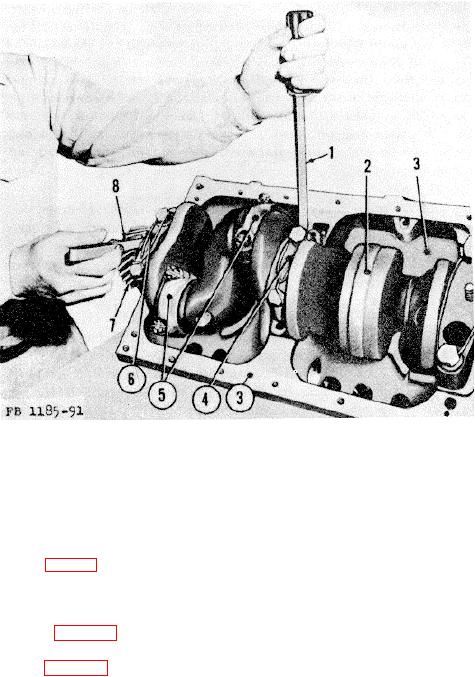

1

Screwdriver

5

Connecting rod bearing cap

2

Crankshaft

6

Front main bearing cap

3

7

Crankshaft timing gear

4

Main bearing cap

8

Feeler gage

Figure 91. Checking crankshaft end play.

(16) Install the key (32, fig. 82), keyway plug (31), and press the fan drive pulley on the crankshaft (19).

(17) Install the starting jaw washer (30) and starting jaw (29).

(18) Install the flywheel (par. 179).

(19) Install the engine (par. 175).

181. Cylinder Block

a. General. The cylinder block of this engine has a main frame with the cylinder and crankcase cast as an integral

part. The block has large water jackets which surround cylinders and valves to provide sufficient cooling. The intake valve

seats are machined on the cylinder block surface. The exhaust valve seats are replaceable and can be removed when

damaged, worn, or cracked.

b. Inspection. Submerge the cylinder block in a strong caustic solvent and let it soak for 2 hours. Remove the

cylinder block and clean it thoroughly with live steam or air pressure. Inspect the block for cracks, breaks, and warpage.

Inspect all water passages and see that they are not plugged with rust, scale, dirt, or foreign matter.

223