TM 5-3895-383-24

10.

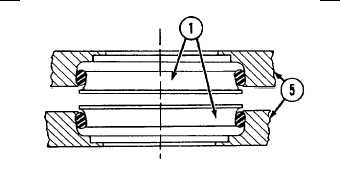

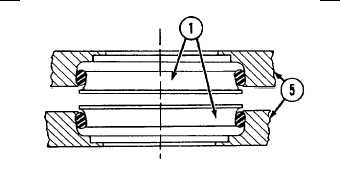

Make sure that both seal ring housings (5) are correctly

aligned and concentric. Slowly move the seals toward

each other.

NOTE: Do not slam the seals together. High impact can

damage the seal components and leakage will

occur.

11.

When the seals are in place, fasten all of the parts

securely.

Hydraulic System Pressure Release

1.

Move the machine to a smooth horizontal location.

Move away tom working machines and personnel. Stop

the engine.

2.

Permit only one operator on the machine. Keep all

other personnel either away from the machine or in view

of the operator.

3.

Move all hydraulic controls to all positions to release any

pressure in the hydraulic system.

4.

Carefully loosen the filler cap on the hydraulic tank to

release any pressure in the tank.

5.

Activate the parking brake.

6.

During certain performance tests it will be necessary to

release the parking brake to help drum movement when

turns are required.

7.

Make sure all hydraulic pressure is released before any

fitting, hose or component is loosened, tightened,

removed or adjusted.

8.

The pressure in the system has now been released and

lines or components can be removed.

Engine Enclosure

Remove & Install Engine Enclosure

7263-010

Tools Needed

A

138-7575

Link Bracket

1

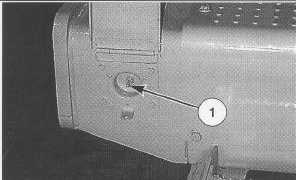

1.

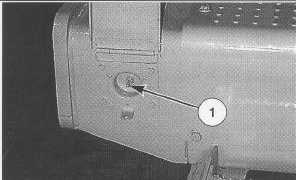

Move the engine enclosure raise/lower switch (1) up to

raise the engine enclosure.

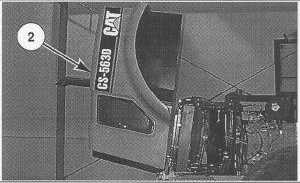

2.

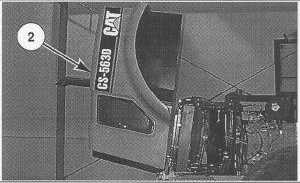

Raise engine enclosure (2) as shown.

14-7