TM 5-3895-379-23-2

FIELD MAINTENANCE

VIBRATORY BEARING RESERVOIR SERVICE

INITIAL SETUP:

References (cont.)

Tools and Special Tools

Tool Kit, General Mechanic's: Automotive

Volume 1, WP 0071

(WP 0289, Table 1, Item 39)

Volume 1, WP 0073

Pan, Drain, 5 Gal Cap.

(WP 0289, Table 1, Item 23)

Equipment Condition

Engine on. (TM 5-3895-379-10)

Materials/Parts

Lubricating Oil, Gear

(WP 0288, Table 1, Item 32, 33, 34)

Rag, Wiping (WP 0288, Table 1, Item 60)

Personnel Required

Construction Equipment Repairer 91L

References

TM 5-3895-379-23P, Figure 131

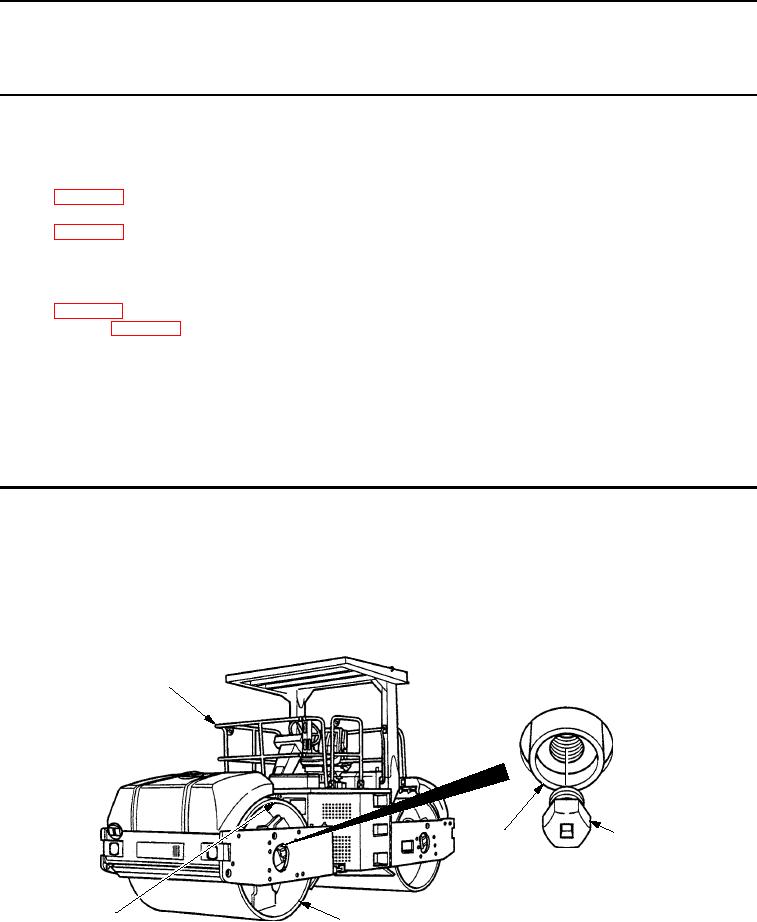

DRAIN

NOTE

Front and rear vibratory bearing reservoir is serviced the same way. Front vibratory bearing

reservoir is shown.

1.

Move roller (Figure 1, Item 1) until bar (Figure 1, Item 5) is at top of drum (Figure 1, Item 4).

1

2

3

M0190SWR

5

4

Figure 1.

Vibratory Bearing Reservoir Drain.

2.

Turn engine off (TM 5-3895-379-10).

03/15/2011Rel(1.8)root(maintwp)wpno(M00200)