DETROIT DIESEL 53

Shop Notes 2.0

satisfactory when the entire surface is a solid dark grey. Bright or exceptionally dark spots indicate defects

and additional lapping is required.

After the surfaces have been refinished, remove the powder by rinsing the lapping blocks in trichloroethyl-

ene and scrubbing with a bristle brush.

When not in use, protect the lapping blocks against damage and dust by storing them in a close fitting wooden

container.

INJECTOR TIMING

If it is suspected that a fuel injector is "out of time", the

injector rack-to-gear timing may be checked without

disassembling the injector.

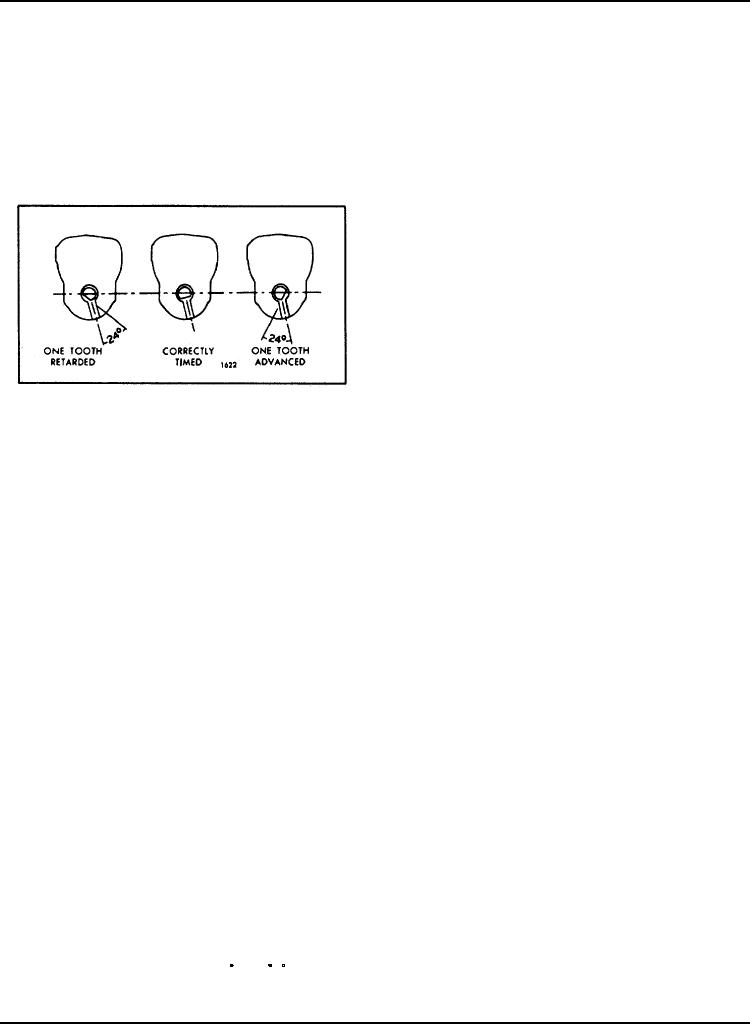

A hole located in the injector body, on the side opposite

the identification tag, may be used to visually determine

whether or not the injector rack and gear are correctly

timed. When the rack is all the way in (full-fuel position),

the flat side of the plunger will be visible in the hole,

indicating that the injector is "in time". If the flat side of

the plunger does not come into: full view ( Fig. 2) and

appears in the "advanced" or :"retarded" position, the

injector should be disassembled and the rack to-gear

Fig. 2 - Injector Rack-to-Gear Timing

timing corrected.

FUEL INJECTOR SPRAY TIPS

Due to a slight variation in the size of the small orifices in the end of each spray tip, the fuel output of an

injector may be varied by replacing the spray tip.

Flow gage J 21085 may be used to select a spray tip that will increase or decrease the fuel injector output for a

particular injector after it has been rebuilt and tested on the comparator.

EFFECT OF PRE-IGNITION ON FUEL INJECTOR

Pre-ignition is due to ignition of fuel or lubricating oil in the combustion chamber before the normal injection

period. The piston compresses the burning mixture to excessive temperatures and pressures and may

eventually cause burning of the injector spray tip and lead to failure of the injectors in other cylinders.

When pre-ignition occurs, all of the injector assemblies should be removed and checked for burned spray tips

or enlarged spray tip orifices.

Before replacing the injectors, check the engine for the cause of pre-ignition to avoid a recurrence of the

problem. Check for oil pull-over from the oil bath air cleaner, damaged blower housing gasket, defective

blower oil seals, high crankcase pressure, plugged air box drains, ineffective oil control rings or dilution of the

lubricating oil.

BLUING INJECTOR BODIES AND NUTS

The appearance of the injector body and nut of a rebuilt injector can be enhanced with an oxide finish obtained

through a dipping process known as "bluing". Pre-mixed compounds are available commercially for preparing

the necessary solutions. Detailed instructions are usually provided with the commercial compounds. An

effective bluing solution can be prepared in the service shop by mixing the following materials:

6 lbs. of sodium hydroxide per gallon of water

3-1/2 lbs. of sodium nitrite per gallon of water

1 ounce of phosphoric acid per gallon of water

The procedure .usually follows five (5) steps in sequence:

1. An alkaline solution bath (180 212

F.) to preclean.

2. A hot or cold water rinse.

Page 2