CAUTION: To prevent the low-speed spring and cap from dropping into the

governor, be careful not to jar the assembly while it is being removed.

b.

Remove the high-speed spring from the high- speed spring plunger and add or remove shims as required to

establish the desired engine no-load speed.

NOTE: For each .010"in shims added, the engine speed will be increased

approximately 10 rpm.

c.

Install the high-speed spring on the plunger and install the spring assembly in the governor housing. Install

the spring retainer in the governor housing and tighten it securely. The maximum no-load speed varies with the

full-load operating speed desired.

d.

Start the engine and recheck the no-load speed. Repeat the procedure as necessary to establish the no-load

speed required.

Adjust Idle Speed

With the maximum no-load speed properly adjusted, adjust the idle speed as follows:

1.

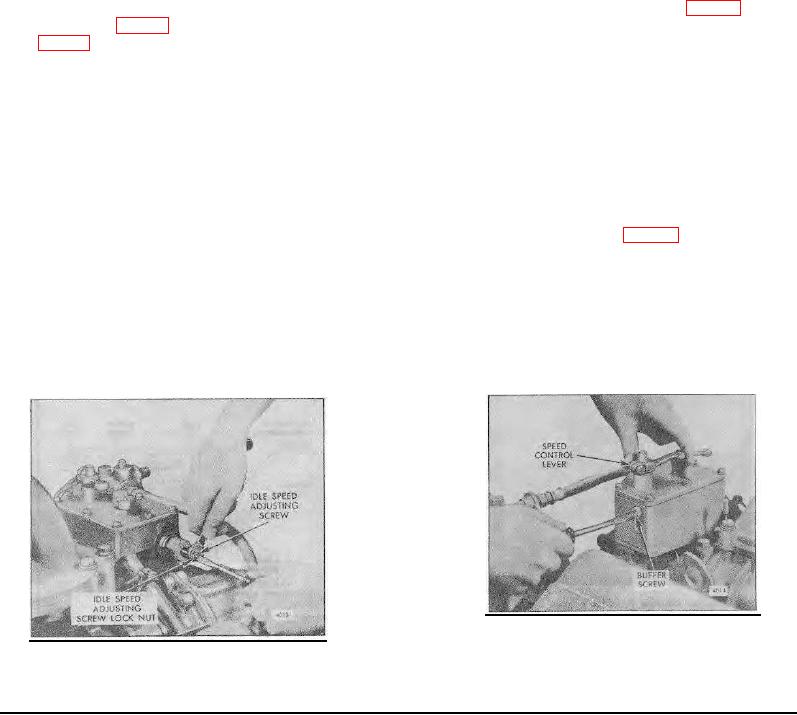

With the engine running at normal operating temperature and with the buffer screw backed out to Fig. 8 - Adjusting

Engine Idle Speed Fig. 9 - Adjusting Buffer Screw avoid contact with the differential lever, turn the idle speed adjusting

screw (Fig. 8) until the engine is operating at approximately 15 rpm below the recommended idle speed.

NOTE: The recommended idle speed for non- EPA certified engines is 500-600

rpm, but may vary with special engine applications.

If the engine has a tendency to stall during deceleration, install a new buffer screw. The current buffer screw uses a

heavier spring and restricts the travel of the differential lever to the off (no-fuel) position.

2.

Hold the idle screw and tighten the lock nut.

3.

Install the high-speed spring retainer cover and tighten the two bolts.

Adjust Buffer Screw

With the idle speed properly set, adjust the buffer screw as follows:

1.

With the engine running at normal operating temperature, turn the buffer screw in (Fig. 9) so it contacts the

differential lever as lightly as possible and still eliminates engine roll.

NOTE: Do not increase the engine idle speed more than 15 rpm with the buffer

screw.

2.

Recheck the maximum no-load speed. If it has increased more than 25 rpm, back off the buffer screw until the

increase is less than 25 rpm.

3.

Hold the buffer screw and tighten the lock nut.

Fig. 9. Adjusting Buffer Screw

Fig. 8. Adjusting Engine Idle Speed

Page 88

DETROIT DIESEL

Engine Tune Up

VARIABLE SPEED MECHANICAL GOVERNOR (OPEN LINKAGE) AND

INJECTOR RACK CONTROL ADJUSTMENT