the outer adjusting screw until it bottoms lightly on the injector control tube. Then alternately tighten both the inner and

outer adjusting screws.

NOTE: Over tightening of the injector rack control lever adjusting screws during

installation or adjustment can result in damage to the injector control tube. The

recommended torque of the adjusting screws is 24-36 in-lbs (3-4 Nm).

IMPORTANT : The above step should result in placing the governor linkage and control

tube assembly in the same position that they will attain while the engine is running at full-

load.

7.

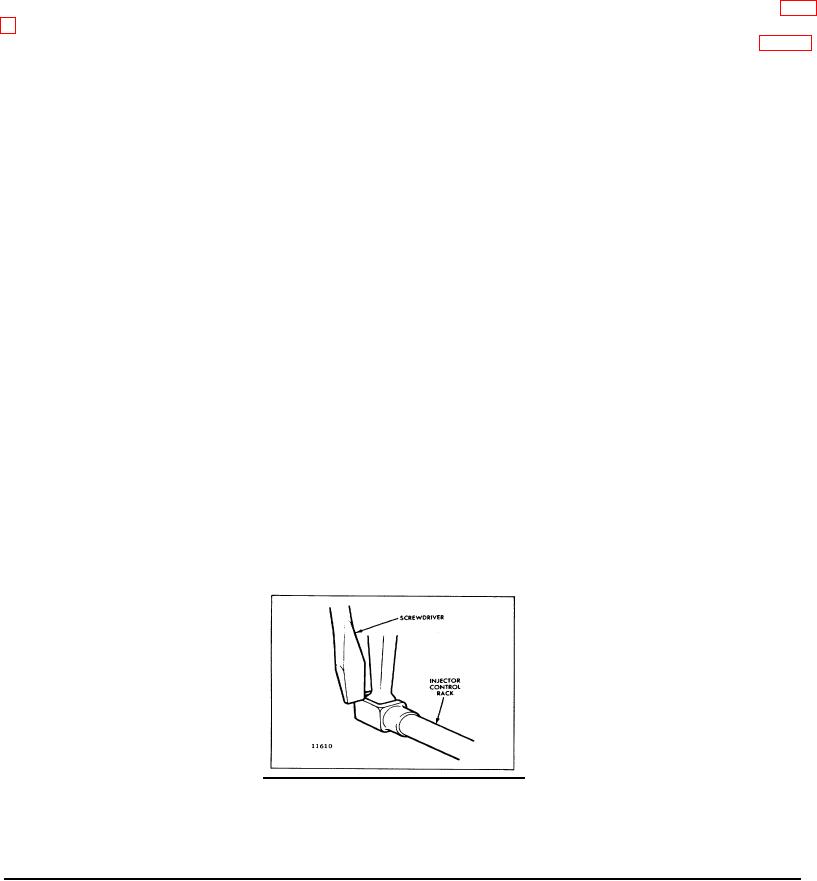

To be sure of the proper rack adjustment, hold the speed control lever in the maximum speed position and press

down on the injector rack with a screw driver or finger tip and note "rotating" movement of the injector control rack (Fig.

4) when the speed control lever is in the maximum speed position. Hold the speed control lever in the maximum speed

position and, using a screw driver, press downward on the injector control rack. The rack should tilt downward (Fig. 5)

and when the pressure of the screw driver is released, the control rack should "spring" back upward.

If the rack does not return to its original position, it is too loose. To correct this condition, back off the outer adjusting

screw slightly and tighten the inner adjusting screw slightly.

The setting is too tight if, when moving the speed control lever from the no-speed to the maximum speed position, the

injector rack becomes tight before the

speed control lever reaches the end of its travel (as determined by the stop under the governor cover). This will result in

a step-up in effort required to move the speed control lever to the end of its travel. To correct this condition, back off the

inner adjusting screw slightly and tighten the outer adjusting screw slightly.

8.

Remove the clevis pin from the fuel rod and the left bank injector control tube lever.

9.

Insert the clevis pin in the fuel rod and the right cylinder bank injector control tube lever and position the No. 3R

injector rack control lever as previously outlined in Step 6 for the No. 3L injector rack control lever.

10. Insert the clevis pin in the fuel rod and the left cylinder bank injector control tube lever. Repeat the check on the 3L

and 3R injector rack control levers as outlined in Step 7. Check for and eliminate any deflection which may occur at the

bend in the fuel rod where it enters the cylinder head.

11. To adjust the remaining injector rack control levers, remove the clevis pin from the fuel rods and the injector

control tube levers, hold the injector control racks in the full-fuel position by means of the lever on the end of the control

tube, and proceed as follows:

a.

Turn down the inner adjusting screw of the injector rack control lever until the screw bottoms (injector control

rack in the full-fuel position).

b.

Turn down the outer adjusting screw of the injector rack control lever until it bottoms on the injector control

tube.

c.

While still holding the control tube lever in the full-fuel position, adjust the inner and outer adjusting screws

to obtain the same condition as outlined in Step 7. Tighten the screws.

CAUTION: Once the No. 3L and No. 3R injector rack control levers are adjusted, do not

try to alter their settings. All adjustments are made on the remaining control racks.

NOTE: Over tightening of the injector rack control tube lever adjusting screws during

installation or adjustment can result in damage to the injector control tube. The

recommended

Fig. 5. Checking Injector Control Rack "Spring"

Page 86

DETROIT DIESEL

Engine Tune Up

torque of the adjusting screws is 24-36 in-lbs (3- Nm).

12. When all of the injector rack control levers are adjusted, recheck their settings. With the control tube lever in the