SECTION 4

HYSTER-CARE MAINTENANCE

seals. Torque bearing retainer nut to specifications listed

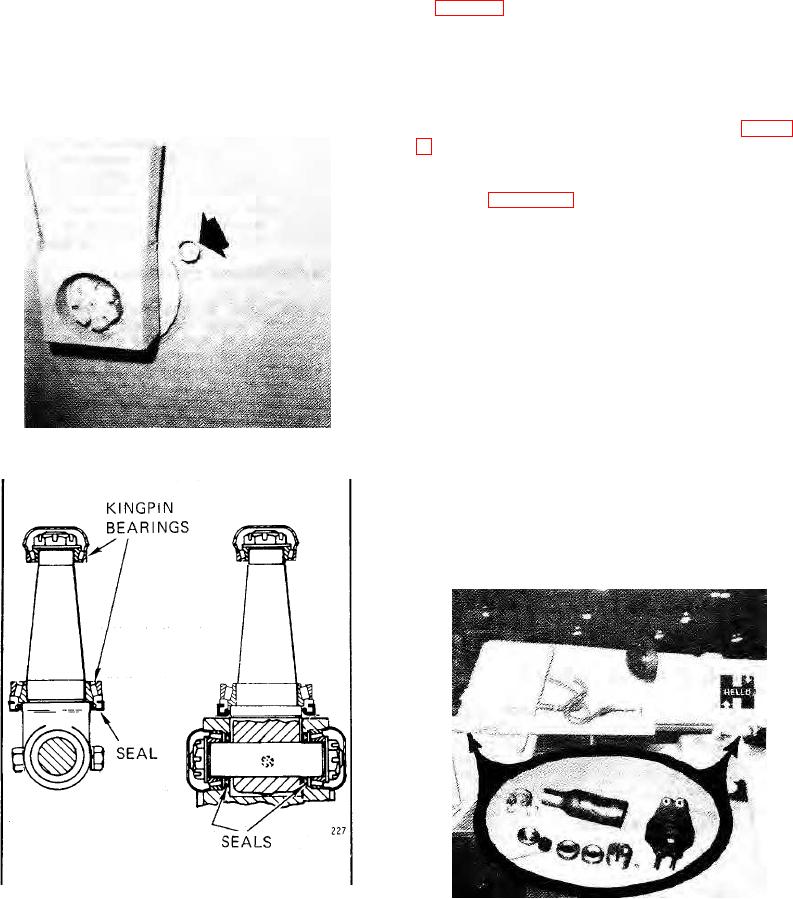

a. Remove the trunnion assembly from the main

in Section 2.

frame.

CAUTION: Use only HYSTER-APPROVED parts.

b. Remove oscillator shaft assembly.

e. Install kingpin bearings and lower seal.

c. Clean, inspect, and re-pack kingpin and oscillator

shaft bearings.

f. Install trunnion assembly into, the frame and torque

d. Install oscillator shaft bearings and new

bearing retainer nut to the specification listed in Section

4-99. STEERING CYLINDER BALL JOINTS

(see figure 4-30).

4-100. The steering ball joints should be re-packed

yearly.

a. Remove rubber dust covers.

b. Disassemble the ball joint on each end of the

cylinder.

c. Clean and inspect components.

d. Pack each ball joint assembly with multi-purpose

grease.

e. Reassemble the ball joints and adjust so there is no

FIGURE 4-28. LUBRICATING GUIDE ROLL

end play.

AXLE BEARINGS.

f. Install rubber dust covers.

CAUTION: Damaged dust covers will not keep out

contaminants. Replace with HY- STER-

APPROVED parts if original dust covers are

damaged.

FIGURE 4-29. TRUNNION ASSEMBLY.

FIGURE 4-30. STEERING CYLINDER

BALL JOINTS.

4-21.