SECTION 4

HYSTER-CARE MAINTENANCE

a. Unscrew the bowl center post fitting at the bottom

of the bowl.

4-74. WATER SPRAY SYSTEM.

b. Remove and discard the element. Inspect filter

head o-ring and bowl gasket. Replace if necessary.

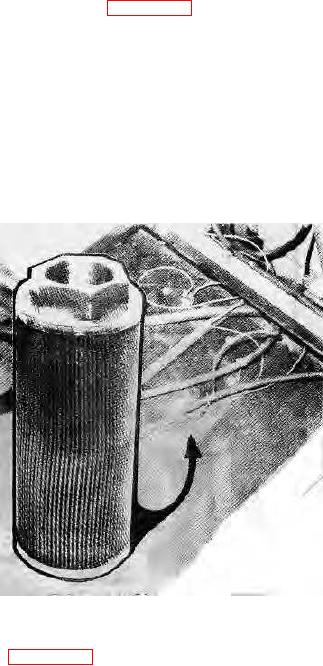

4-75. FILTERS (see figure 4-23).

c. Wipe the bottom section of the filter head using a

4-76. The non-corrosive sump filter normally requires no

clean, lint-free cloth. Install a new o-ring in the filter

maintenance because of the self cleaning action of the

head if required. Use a light film of grease to hold the o-

water washing back and forth in the tank. If excessive

ring in place if necessary.

foreign material accumulates in the tank, the filter and

the tank will need cleaning. The filter can be inspected

CAUTION: Do not use lint-type cloth to clean hydraulic

by removing the tank access plate.

components. Lint deposits can affect the

operation of the system.

4-77. The tank inlet screen filter should be periodically

cleaned when the water does not readily pass through.

d. Install a new element in the filter bowl.

The screen lifts out of the tank freely after snap ring is

removed.

CAUTION:

Use only

HYSTER-APPROVED

filter

elements.

e. Screw the assembled filter bowl into the filter head.

When tightening the center post, hold the bowl from

turning because it may stretch the o-ring out of shape

and cause suction leakage. Tighten the center post to a

maximum of 20 ft.-lbs.(2.8 kg-m).

4-71. The throw-a-way return filter should be replaced at

1,000 hours of operation or every year, whichever

occurs first. Always change the return filter if the suction

filter is replaced.

a. Unscrew the filter from the filter head and discard

the filter.

b. Wipe bottom of the filter using a clean, lint-free

cloth.

CAUTION: Use only HYSTER-APPROVED filters.

c. Apply a film of oil or grease to the new filter gasket

(integral with filter).

FIGURE 4-23. WATER FILTER

d. Hand turn the filter into the filter head until the

gasket just makes contact. Then tighten one-quarter turn

4-78. MANIFOLD AND NOZZLES (see

only.

4-79. The nozzles are mounted so they receive water

from the center of the manifold tube where corrosion

and sediment are minimized. This eliminates most of

the nozzle plugging problems. Periodically the end caps

on the water spray manifold should be removed and the

sediment blown from the manifold.

4-80. STORAGE.

4-81. Drain the entire water spray system to

4-18.