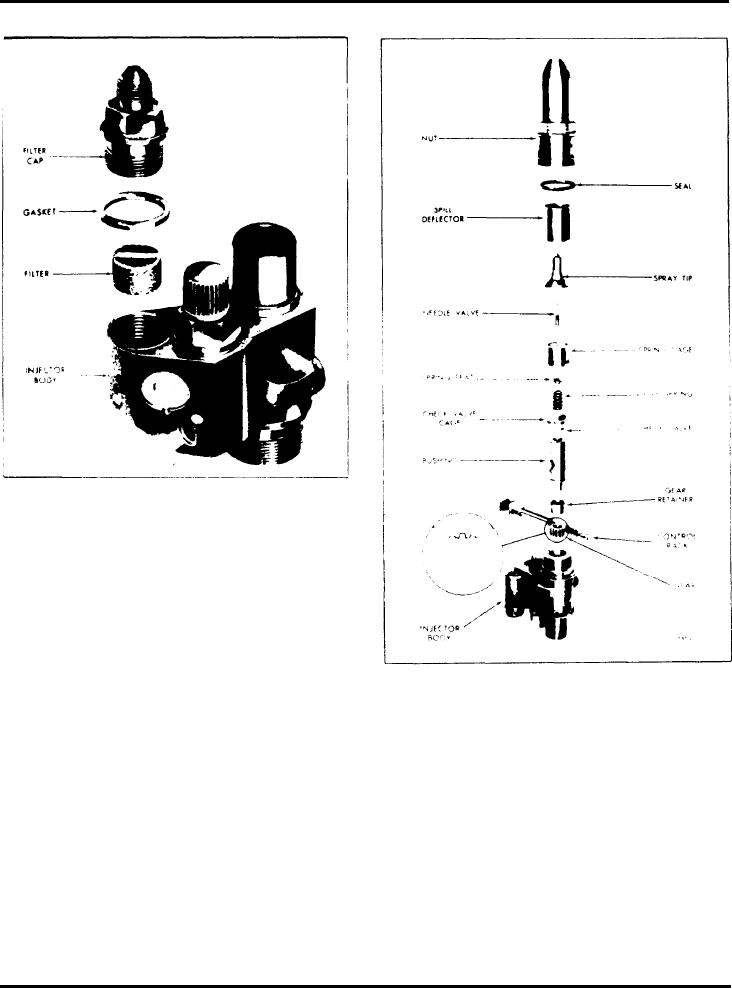

Fuel Injector

2.1.1

DETROIT DIESEL 53

Fig. 35 - Details of Injector Filters and Caps

and Their Relative Location

Inspect both ends of the spill deflector for sharp edges

or burrs which could create burrs on the injector body

or injector nut and cause particles of metal to he

introduced into the spray tip and valve parts. Remove

burrs with a 500 grit stone.

Inspect the follower spring for visual defects. Then

check the spring with spring tester J 9666 and an

accurate torque wrench.

Fig. 36 - Injector Rack, Gear, Spray Tip and

Valve Assembly Details and Relative Location

The current injector follower spring (.142 " diameter

of Parts

wire) has a free length of approximately 1.504 " and

should be replaced when a Ioad of less than 70 Ibs. will

surface at this point will result in high fuel

compress it to 1.028 "

consumption and contamination of the lubricating oil.

Replace any loose injector body plugs or a loose dowel

It is recommended that at the time of overhaul, all

pin. Install the proper number tag on a service

injectors in an engine he converted to the current

replacement injector body.

spring (.142 " diameter wire) which will provide

improved cam roller to shaft follow However, in the

event that one or two injectors are changed. the

Inspect the injector plunger and hushing for scoring.

remdining injectors need not be reworked to

erosion, chipping or wear. Check for sharp edges on

incorporate the current spring.

that portion of the plunger which rides in the gear.

Remove any sharp edges with a 500 grit stone. Wash

Check the seal ring area on the injector body for burrs

the plunger after stoning it. Injector Bushing

or scratches. Also check the surface which contacts the

Inspectalite J 21471 can be used to check the port

injector bushing for scratches, scuff marks, or other

holes in the inner diameter of the bushing for cracks

damage. If necessary, lap this surface. A faulty sealing

or chipping. Slip the plunger into the bushing and

Page 16