1.6

DETROIT DIESEL 53

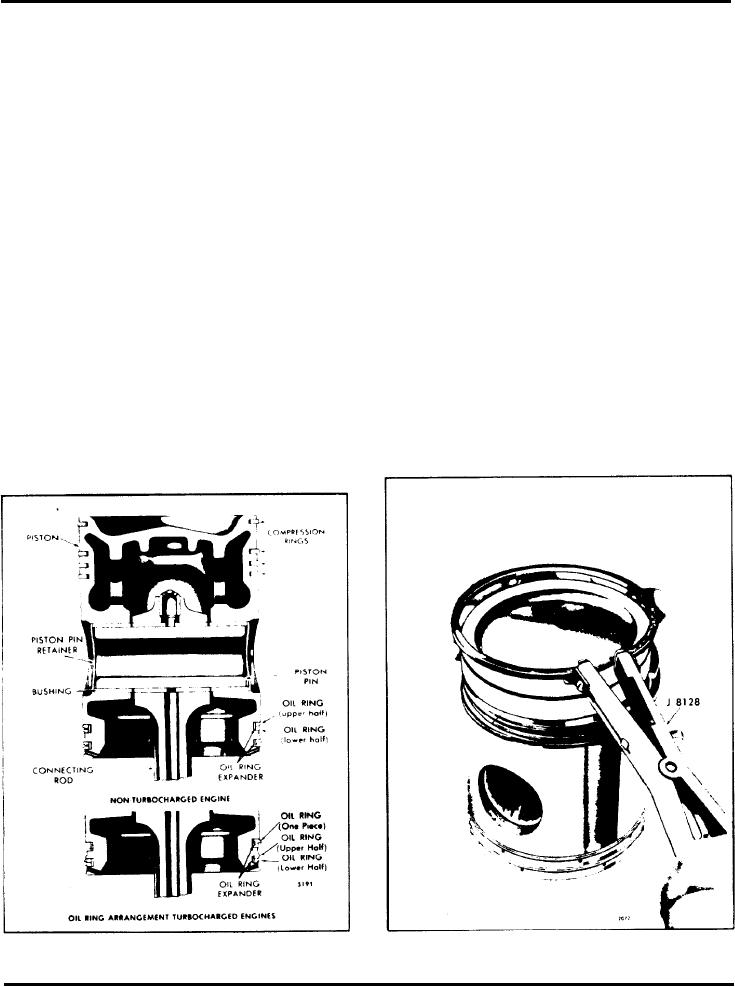

P I S T O N AND PISTON RINGS

hardened, floating piston pin. After the piston pin has

The trunk type malleable iron piston (Fig. 1) is plated

been installed, the hole in the piston at each end of the

with a protective coating of the which permits close

pin is sealed with a steel retainer. Thus lubricating oil

fitting. reduces scuffing and prolongs piston life. The

returning from the sprayed underside of the piston

top of the piston forms the combustion chamber bowl

head and working through the grooves in the piston

and is designed to compress the air into close

pin bushings is prevented from reaching the cylinder

proximity to the fuel spray.

walls.

Each piston is internally braced with fin-shaped ribs

and circular struts. scientifically designed to draw heat

Each piston is fitted with compression rings and oil

rapidly from the piston crown and transfer it to the

control rings (Fig. 1 ).

lubricating oil spray to ensure better control of piston

ring temperature.

Equally spaced holes arc drilled just below each oil

control ring land to permit the excess oil that is

The piston is cooled by a spray of lubricating oil

scraped off the cylinder walls to return to the

directed at the underside of the piston head from a

nozzle in the top of the connecting rod, by fresh air

from the blower to the top of the piston and indirectly

by the water Jacket around the cylinder.

Inspect Piston Rings

Each piston is balanced to close limits by machining a

balancing rib. provided on the inside at the bottom of

When an engine is hard to start, runs rough or lacks

the piston skirt.

power, worn or sticking compression rings may he the

cause. Replacing the rings will aid in restoring engine

Two bushings, with helical grooved oil passages, are

operation to normal.

pressed into the piston to provide a bearing for the

Fig. 2 - Removing or Installing Piston Ring

Fig. 1 - Typical Piston Assembly

SEC. 1.6 Page 1

April, 1974