DETROIT DIESEL

SECTION 8

TROUBLE S H O O T I N G

Certain abnormal conditions which sometimes inter-

4. Start the engine and hold an injector follower down

fere with satisfactory engine operation, together with

with a screw driver to prevent operation of the

methods of determining the cause of such conditions,

injector. If the cylinder has been misfiring, there will

are covered on the following pages,

be no noticeable difference in the sound and operation

of the engine. If the cylinder has been firing properly,

Satisfactory engine operation depends primarily on:

there will be a noticeable difference in the sound and

operation when the injector follower is held down.

This is similar to short-circuiting a spark plug in a

1. An adequate supply of air compressed to a

gasoline engine.

sufficiently high compression pressure.

2. The injector of the proper amount of fuel at the

5. If the cylinder is firing properly, repeat the

right time.

procedure on the other cylinders until the faulty one

has been located.

Lack of power, uneven running, excessive vibration,

stalling at idle speed and hard starting may be caused

6. If the cylinder is misfiring, check the following:

by either low compression, faulty fuel injection in one

or more cylinders, or lack of sufficient air.

a. Check the injector timing (refer to Engine Tune-

Up Procedure).

Since proper compression, fuel injection and the

proper amount of air are important to good engine

b. Check the compression pressure.

performance, detailed procedures for their investiga-

tion are given as follows:

c. Install a new injector.

d. If the cylinder still misfires, remove the cam

follower and check for a worn cam roller,

locating a Misfiring Cylinder

camshaft lobe, bent push rod or worn rocker arm

1. Start the engine and run it at part load until it

bushings.

reaches normal operating temperature.

7. If installation of a new injector does not eliminate

2. Stop the engine and remove the valve rocker

misfiring, check the compression pressure.

cover(s). Discard the gasket(s).

3. Check the valve clearance. The clearance should be

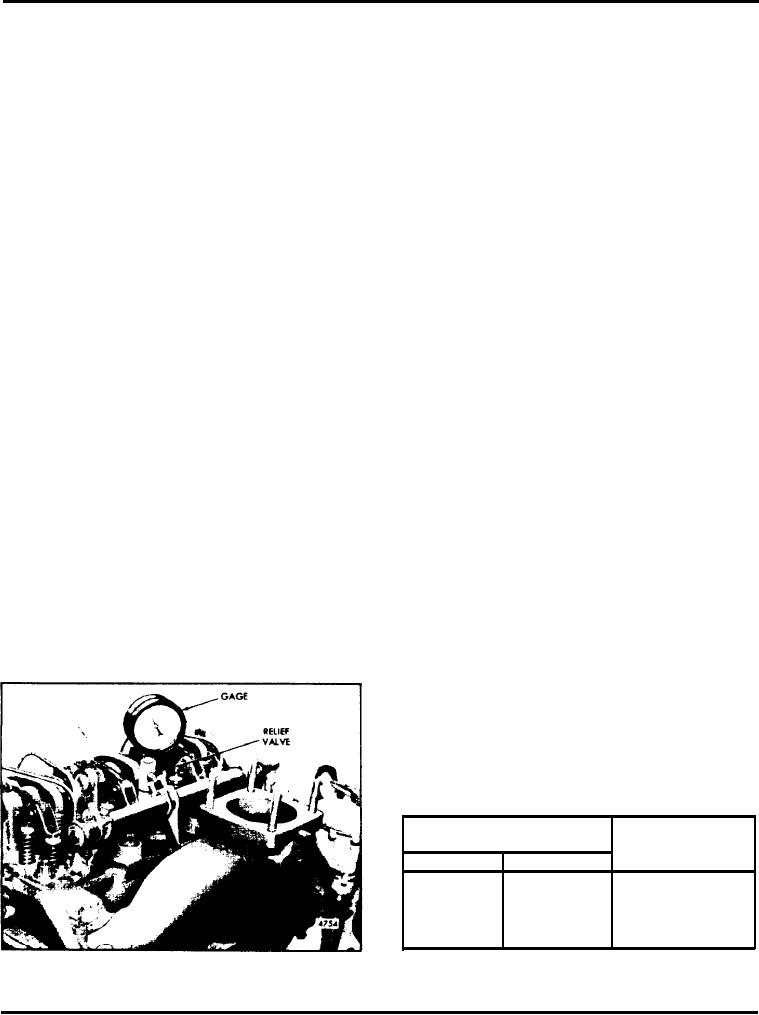

Checking Compression Pressure

.009" (two valve cylinder head) or .024" (four valve

cylinder head).

Compression pressure is affected by altitude as shown

in Table 1.

Check the compression pressure as follows:

1. Start the engine and run it at approximately one-

half rated load until normal operating temperature is

reached.

Minimum Compression

Altitude, Feet

Pressure, psi

Above Sea Level

Std. Engine

"N" Engine

430

0

540

400

2,500

500

370

5,000

465

340

7,500

430

315

395

10,000

Fig. 1 - Checking Compression Pressure

TABLE 1

Page 113