SECTION 4

MAINTENANCE

4-72. Make sure that the compressor takes in

b. Load compactor to desire weight.

clean air. Install the air strainer properly and

keep it clean. Air intake connections must be

c. Loosen jam nut and turn adjusting screw

properly installed and maintained.

until the center wheel is vertical using wheel

rim for reference point (see figure 4-10).

4 - 7 3 . Check mounts for tightness and drive

belt for proper tension.

d. Tighten jam nut.

4-74. Inspect oil supply line and water lines for

e. Readjust when ballast weight is changed.

proper installation. Check the unloader mech-

anism for operation.

NOTE: If the wheel is tilted to the right, it is

loaded too much. If it tilts to the left, it

4-75. AIR LEAKAGE TESTS.

is not sufficiently loaded.

4-76. Leakage past the discharge valves can be

detected by removing the discharge line,

applying shop air back through the discharge

port and listening for escaping air.

4-77. The discharge valves and the unloader

pistons can be checked for leakage by building

up the air system until the governor cuts out,

and by stopping the engine. Listen for

e s c a p i n g air at the intake. To pin-point air

leakage, squirt soapy water around the

unloader pistons. If they don t leak, then the

discharge valves may leak.

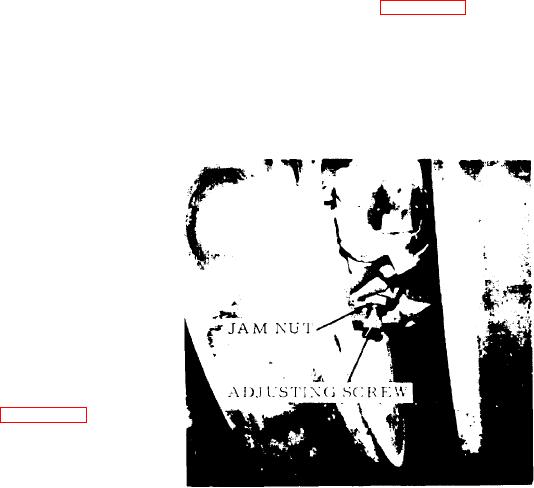

4-78. REAR CENTER WHEEL SPRING

ADJUSTMENT (see figure 4-10).

NOTE: Spring adjustment depends on the rear

ballast load.

a. Place the compactor on a flat, even

FIGURE 4-10. REAR CENTER WHEEL SPRING

surface.

ADJUSTMENT.

4-12.