TM 5-3895-346-14

AXLE

DRIVE CARE AND MAINTENANCE

IMPORTANT

To loosen the dowels, hold at 1 -inch diameter brass drift against the center of the axle shaft head, INSIDE

THE CIRCULAR DRIVING LUGS. Strike the drift a sharp blow with a 5- to 6- pound hammer or sledge. A 1 -

inch diameter brass hammer is an excellent and safe drift.

CAUTION

Do not hit the circular driving lugs on the shaft head-this may cause the lugs to

shatter and splinter. Do not use chisels or wedges to loosen the shaft or dowels-

this will damage the hub, shaft and oil seal.

7.

Remove axle shafts and carefully remove outer oil seal assemblies.

8.

Remove wheels.

9.

Place axle assembly in heavy vise, holding by the tube on the case half.

DISASSEMBLE AXLE

1.

Before disassembling, place length of pipe or suitable support, slightly smaller than axle shaft

splines, approximately two-thirds through axle from the case side to prevent dropping the differential assembly.

2.

Remove bolts, nuts, and washers from case and cover and remove cover half.

3.

Remove differential and gear assembly.

4.

Remove pipe.

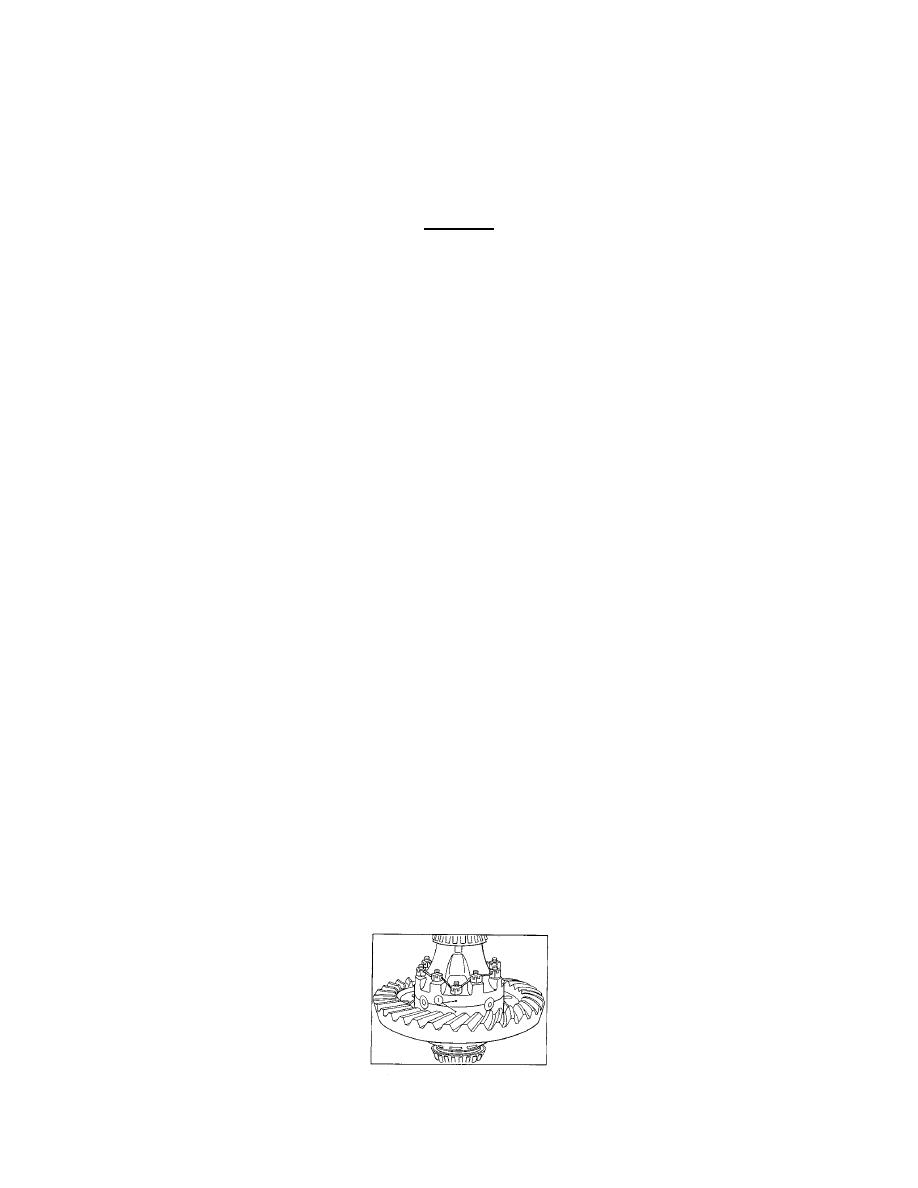

DISASSEMBLE DIFFERENTIAL AND GEAR ASSEMBLY

1.

If original identification marks are not clear, mark differential case halves with a punch or chisel

(refer to Fig. 3) before disassembling, for correct alignment when reassembling.

2.

Cut lock wire, remove bolts or capscrews, and separate case halves (refer to Fig. 3).

3.

Remove spider, pinions, side gears, and thrust washers (refer to Fig. 3).

4.

Remove rivets and separate gear and case if required (refer to Fig. 4).

a.

Carefully centerpunch rivets in center of head.

b.

Use drill 1/32-inch smaller than body of rivet to drill through head.

c.

Press out rivets.

5.

Remove differential bearings with bearing puller if necessary to replace (refer to Fig. 5).

Figure 3.

621