TM 5-3895-346-14

HYDROSTATIC SYSTEM

MOTOR REPAIR

To check the shaft end play, assemble the shaft and bearings, housing, end cap and gasket (refer to Fig. 17).

The shaft end play should be from 0.006 inch to 0.016 inch. If adjustment is necessary, a shim can be placed

under the bearing race in the end cap.

Figure 17.

Figure 19.

Place the fixed swashplate over the shaft-bearing assembly and place into housing locating the notch in the

swashplate on the pin in the housing (refer to Fig. 18).

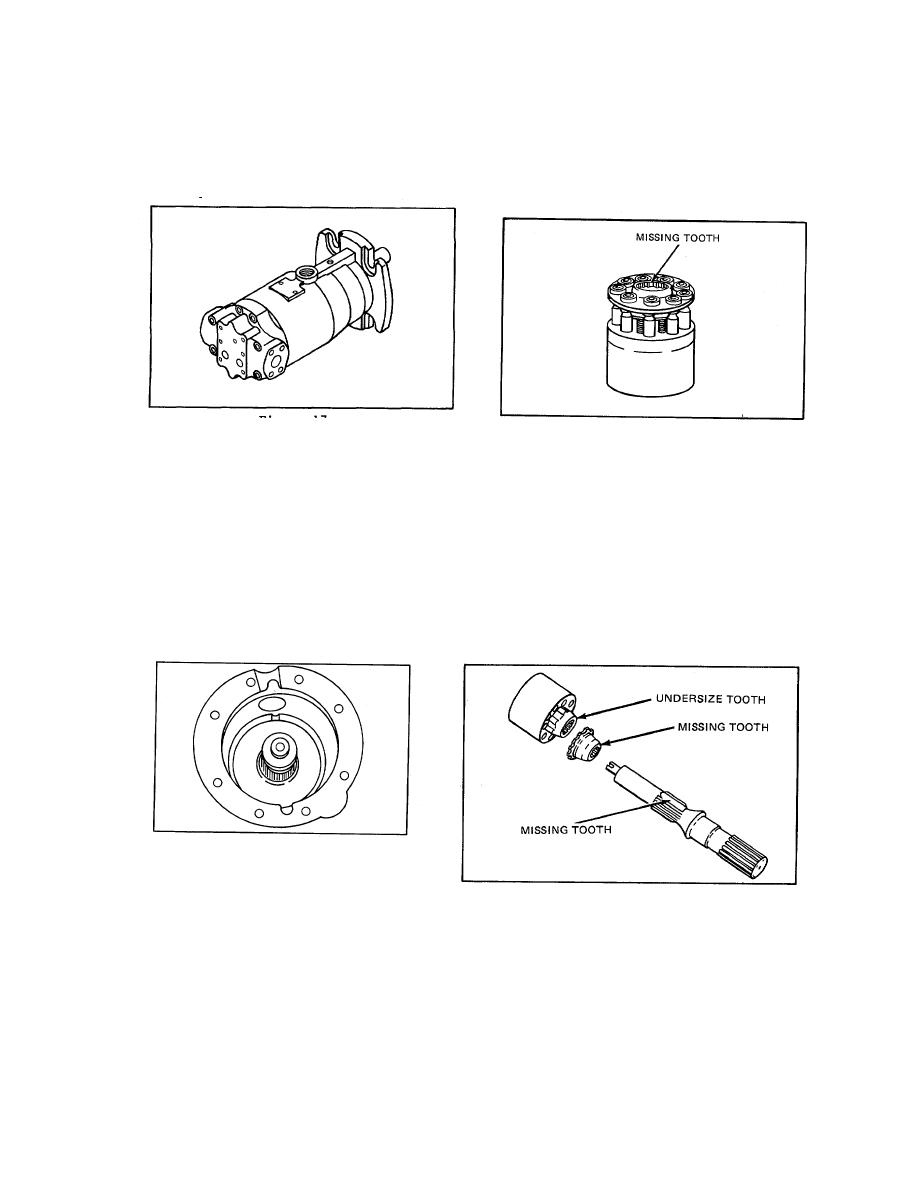

The cylinder block should be installed next. It is necessary to check the alignment of certain parts. There is no

special relationship of pistons, bores, springs, etc.; however, the alignment of the ball guide and cylinder block

splines is critical. The undersized tooth in the spline of the cylinder block must line up with the missing tooth in

the ball guide spline. These in turn line up with a missing tooth on the shaft spline. The hole for the bearing

plate locating pin in the cylinder block face is in line with the undersize tooth in the cylinder block and provides

an assembly guide (refer to Figs. 19 and 20).

Figure 18.

Figure 20.

Lubricate the swashplate, slippers, pistons, and bores with clean hydraulic oil. Hold the shaft on the external

end, align the missing shaft tooth with the missing ball guide tooth using the locating pinhole as a guide. Slide

the cylinder block assembly onto shaft and

523