TM 5-3895-346-14

COOLANT SPECIFICATIONS

ENGINE OVERHAUL

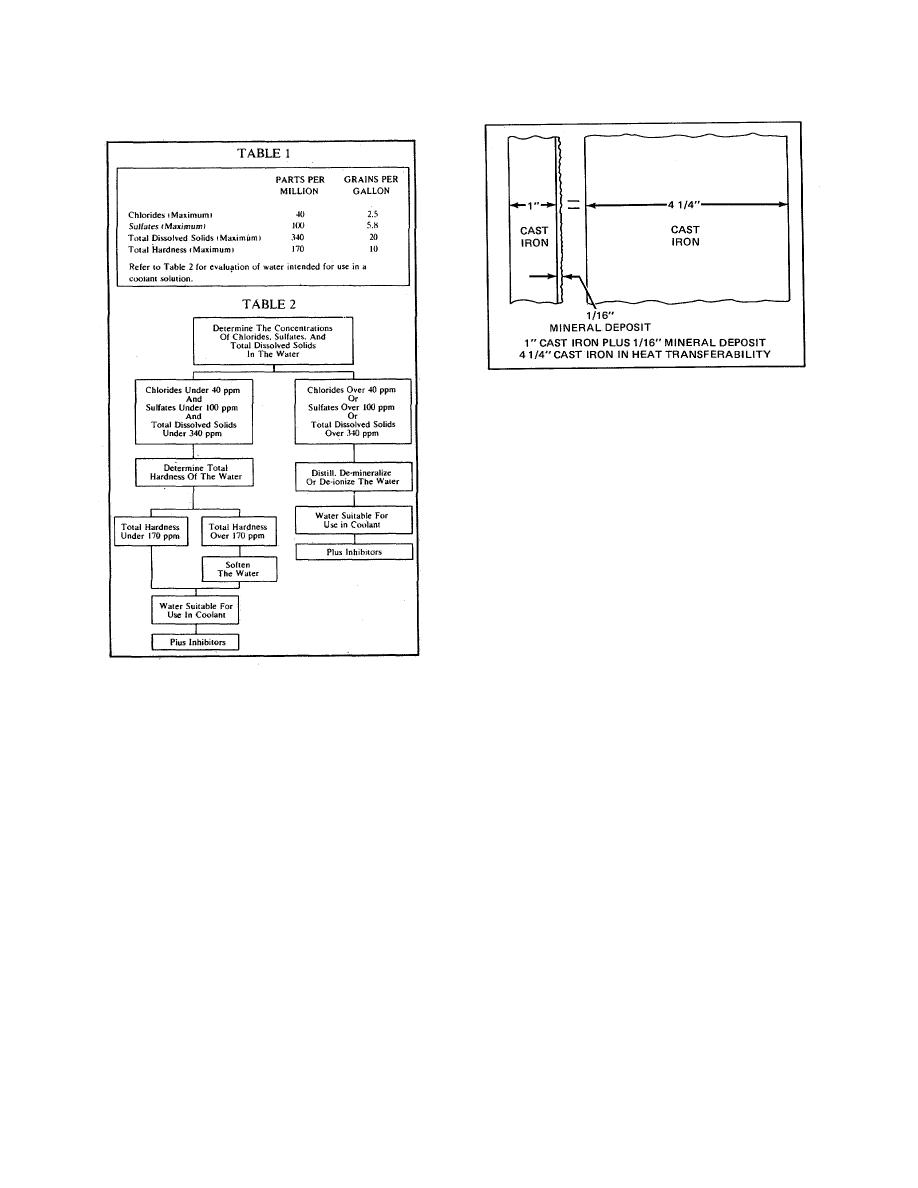

Figure 2. Heat Transfer Capacity

Figure 1. Water Characteristics

considerations, has deemphasized their use in favor of nonchromates. Care should be exercised in handling

these materials due to their toxic nature.

Chromate inhibitors should not be used in permanent-type antifreeze solutions. Chromium hydroxide,

commonly called green slime", can result from the use of chromate inhibitors with permanent type antifreeze.

This material deposits on the cooling system passages, reducing the heat transfer rate (Fig. 2), and results in

engine overheating. Engines which have operated with a chromate-inhibited water must be chemically cleaned

before the addition of permanent-type antifreeze. A commercial heavy-duty descaler should be used in

accordance with the manufacturer's recommendation for this purpose.

Soluble Oil

Soluble oil has been used as a corrosion inhibitor for many years. It has, however, required very close

attention relative to the concentration level due to adverse effects on heat transfer if the concentration exceeds

1% by volume. For example: 1-1/4% of soluble oil in the cooling system increases fire deck temperatures 6%

and a 2-1/2% concentration raises fire deck temperature up to 15%. Soluble oil is NOT RECOMMENDED as a

corrosion inhibitor.

Nonchromates

Nonchromate inhibitors (borates, nitrates, nitrites, etc.) provide corrosion protection in the cooling system with

the basic advantage that they can be used with either water or a water and permanent-type antifreeze solution.

406