TM 5-3895-346-14

ENGINE OVERHAUL

OIL PUMP

an assembly. Remove the oil pump inlet elbow (if used) and gasket from the engine front cover.

5. Remove the lower engine front cover.

6. Remove the six bolts and lock- washers (if used) which attach the pump assembly to the engine front cover

(Fig. 1) and withdraw the pump assembly from the cover.

Disassemble Oil Pump

If the oil pump is to be disassembled for inspection or reconditioning, proceed as follows:

1. Refer to Fig. 5 or 6 and remove the two drive screws holding the pump cover plate to the pump body.

Withdraw the cover plate from the pump body.

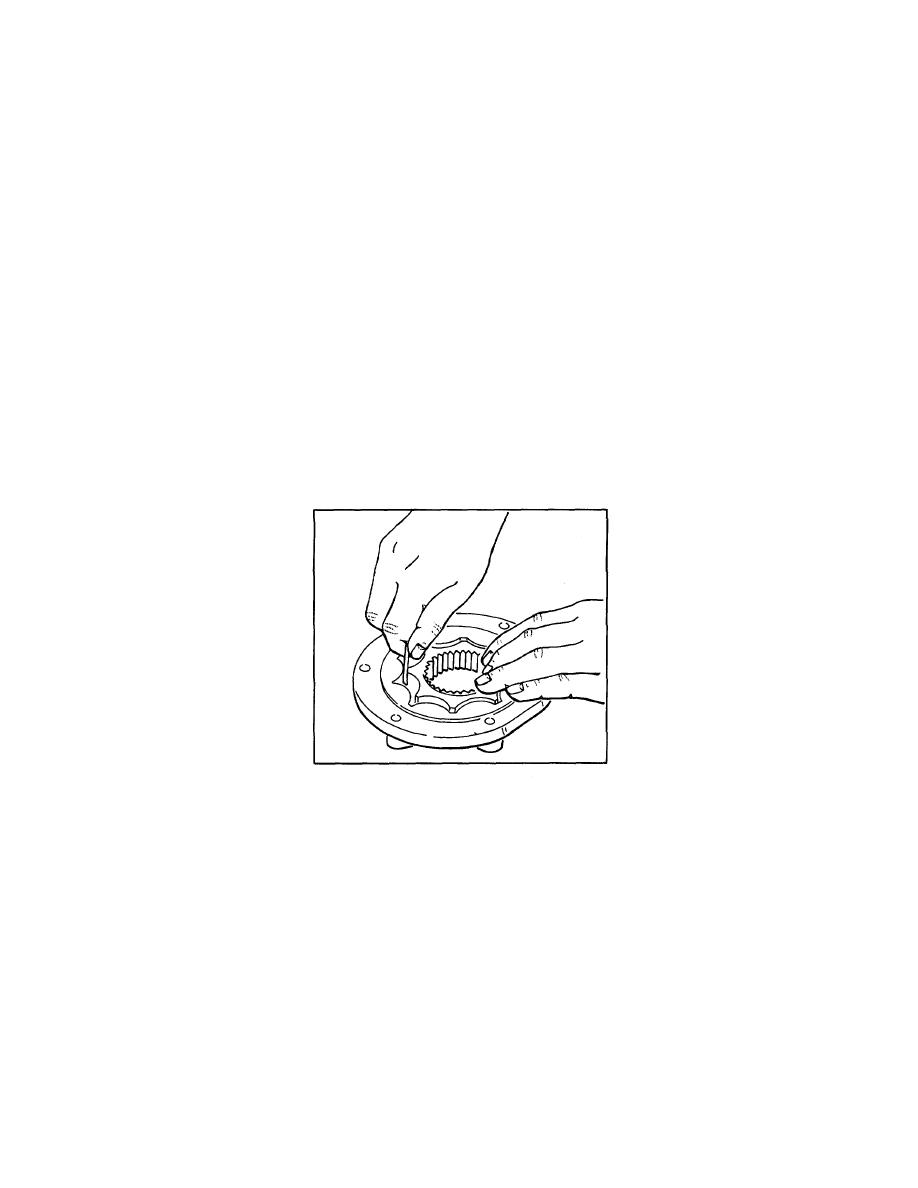

2. Remove the inner and outer rotors from the pump housing.

Inspection

Wash all of the parts in clean fuel oil and dry them with compressed air. The greatest amount of wear in the oil

pump-is imposed on the lobes of the inner and outer rotors. This wear may be kept to a minimum by using

clean oil. If dirt and sludge are allowed to accumulate in the lubricating system, excessive rotor wear may

occur in a comparatively short period of time. Inspect the lobes and faces of the pump rotors for scratches or

burrs and the surfaces of the pump body and cover plate for scoring. Scratches or score marks may be

removed with an emery stone. Measure the clearance between the inner and outer rotors at each lobe (Fig. 3).

Figure 3. Measuring Rotor Clearance

The clearance should not be less than 0.004 inch or more than 0.011 inch. Measure the clearance from the

face of the pump body to the side of the inner and outer rotor with a micrometer depth gage (Fig. 4). The

clearance should not be less than 0.001 inch or more than 0.0035 inch. Inspect the splines of the inner rotor

and the oil pump drive gear. If the splines are excessively worn, replace the parts. The rotors are serviced as

matched sets, therefore, if one rotor needs replacing, replace both rotors. Remove the oil inlet screen from the

oil inlet pipe and clean both the screen and the pipe with fuel oil and dry them-with compressed air. Replace

the inlet pipe flange seal ring with a new seal ring.

Assemble Oil Pump

After the oil pump parts have been cleaned and inspected, refer to Fig. 5 or 6 and assemble the pump as

follows:

1. Lubricate the oil pump outer rotor with engine oil and place it in the pump body.

311