TM 5-3895-346-14

OIL PUMP

ENGINE OVERHAUL

LUBRICATING OIL PUMP

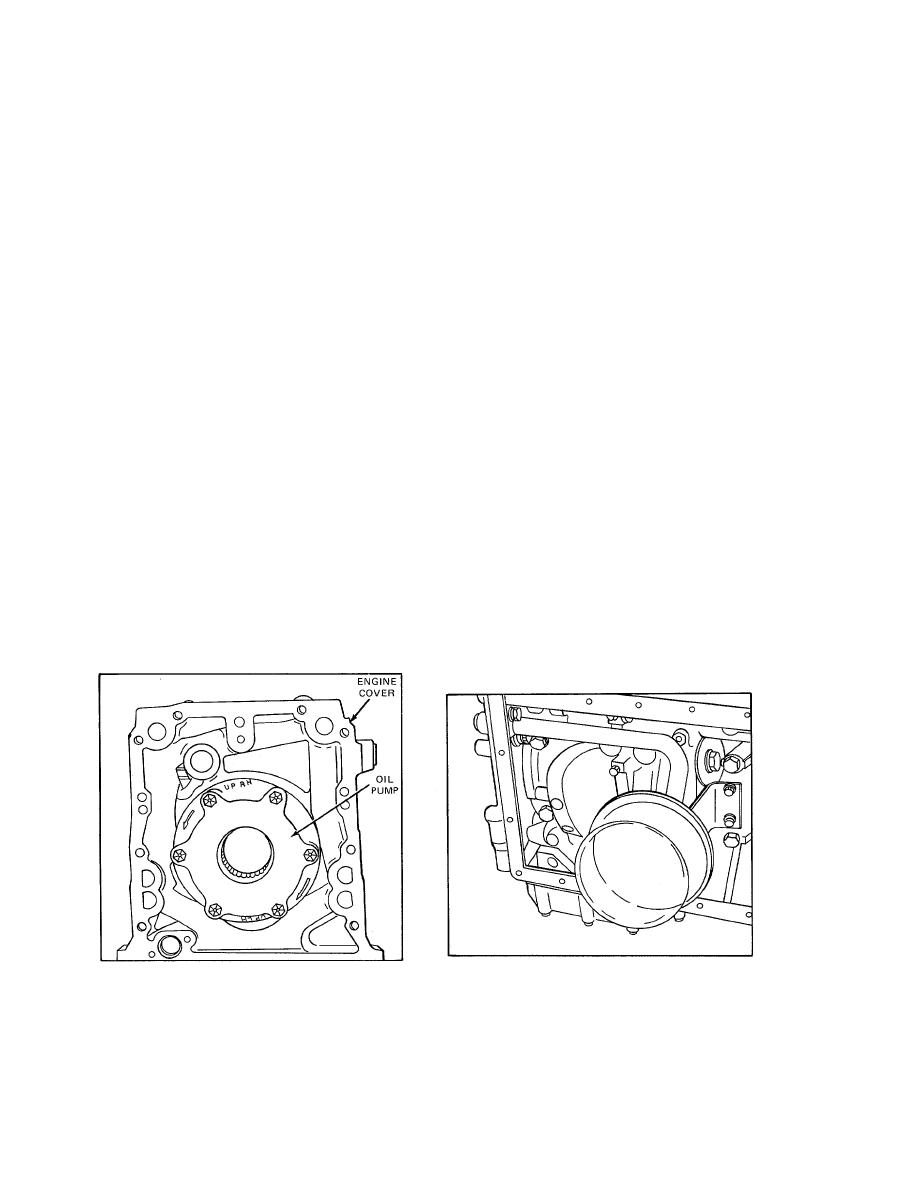

The lubricating oil pump, assembled to the inside of the lower engine front cover as illustrated in Fig. 1, is of

the rotor-type in which the inner rotor is driven by a gear pressed on the front end of the crankshaft. The outer

rotor is driven by the inner rotor. The bore in the pump body, in which the outer rotor revolves, is eccentric to

the crankshaft and inner rotor. Since the outer rotor has nine cavities and the inner rotor has eight lobes, the

outer rotor revolves at eight-ninths crankshaft speed. Only one lobe of the inner rotor is in full engagement with

the cavity of the outer rotor at any given time, so the former can revolve inside the latter without interference.

Operation

As the rotors revolve, a vacuum is formed on the inlet side of the pump and oil is drawn from the crankcase,

through the oil pump inlet pipe and a passage in the front cover, to the inlet port, and then into the rotor

compartment of the pump. Oil drawn into the cavities between the inner and outer rotors on the inlet side of

the pump is then forced out under pressure through the discharge port into a passage in the front cover, which

leads to the lubricating oil filter and cooler, and is then distributed throughout the engine.

If a check of the lubrication system indicates improper operation of the oil pump, remove and disassemble it as

outlined below.

Remove Oil Pump

1. Drain the oil from the engine.

2. Remove the crankshaft pulley, fan pulley, support bracket, and any other accessories attached to the front

cover.

3. Remove the oil pan.

4. Refer to Fig. 2 and remove the four bolts which attach the oil pump inlet pipe and screen assembly to the

main bearing cap and engine front cover or oil pump inlet elbow. Slide the flange and the seal ring on the inlet

pipe and remove the pipe and screen as

Figure 1. Typical Right-Hand Rotation

Figure 2. Typical Oil Pump Inlet Pipe

Oil Pump Mounting

and Screen Mounting

310