TM 5-3895-346-14

ENGINE OVERHAUL

SHOP NOTES

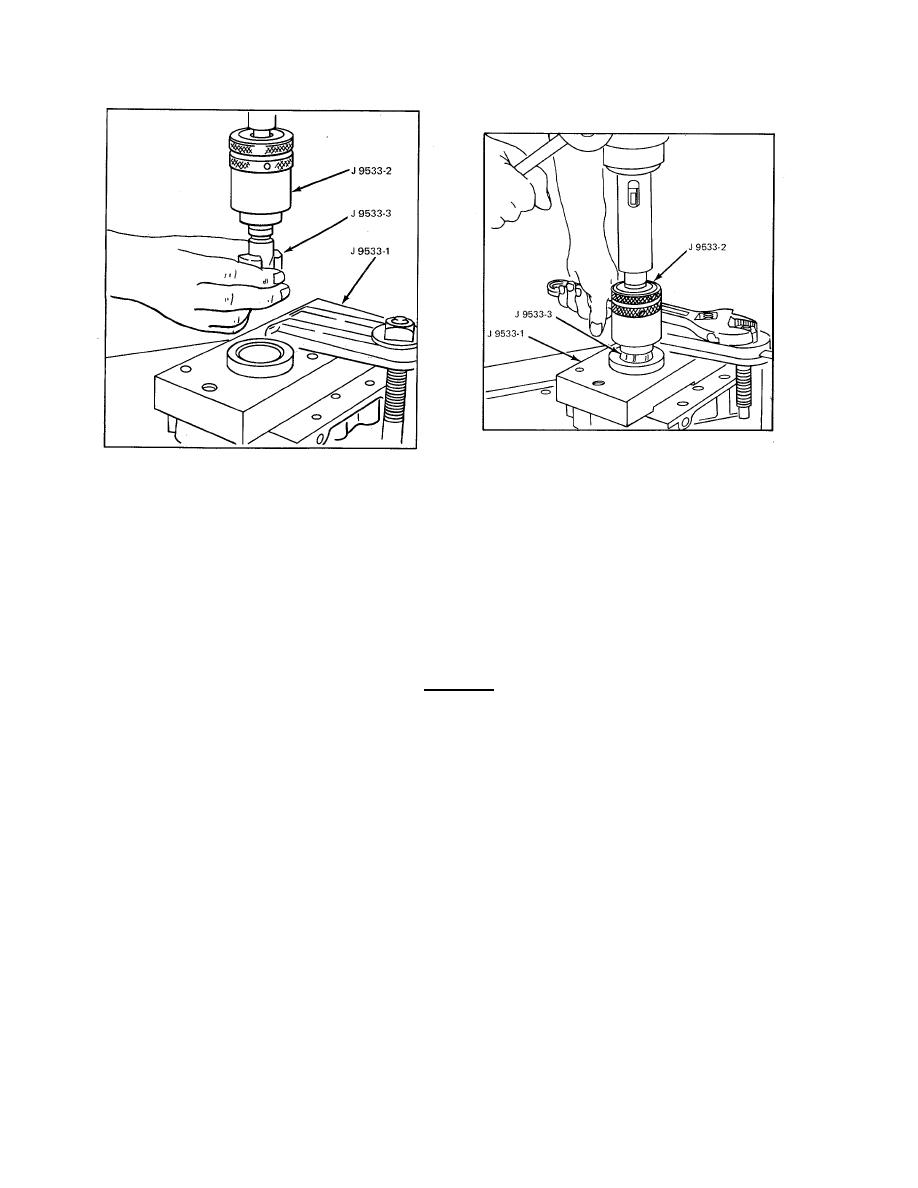

Figure 2. Install Cutting Tool in Holder

Figure 3. Positioning Cutting Tool in Fixture Guide

5.

Position the cutting tool in the fixture guide as shown in Fig. 3. Operate the drill press at 75-100

rpm so as to center the cutting tool in the rotor shaft hole. Tighten the clamp.

6.

Lubricate the cutting tool and the area of the end plate that is being reworked with a lubricant

(mineral spirits or fuel oil).

7.

Operate the drill press at 300- 350 rpm and slowly counterbore the hole until the collar of the tool

holder is approximately 1/16 inch from the fixture guide. Then reduce the speed of the drill press to 75-100

rpm and continue counterboring until the collar contacts the top of the guide.

CAUTION

Raise the cutting tool periodically during the drilling operation

and apply additional lubricant.

8.

Stop the drill press and remove the rough cutting tool.

9.

Insert finish cutting tool J 9533-4 in the holder. Lubricate the cutting tool and the end plate.

Operate the drill press at 75-100 rpm and finish-cut the counterbore. Feed the cutting tool into the work slowly.

10. Remove the finish cutting tool and install an end mill to machine the additional 1.060 to 1.125-

inches- diameter counterbore. The total depth of the combined counterbores is 0.440 inch (Fig. 4). The

additional counter- bore provides proper oil drain back from the oil seal area.

11. Remove the fixture from the end plate. Wipe the cuttings from the end plate and fixture and dry

the plate and fixture with compressed air. Remove any burrs from the edge of the oil hole.

301